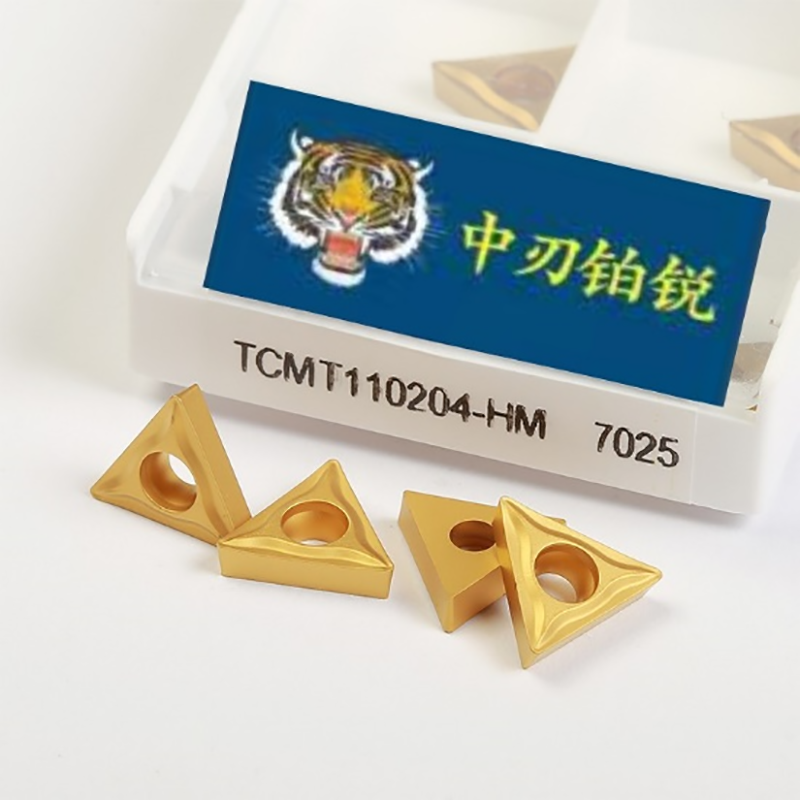

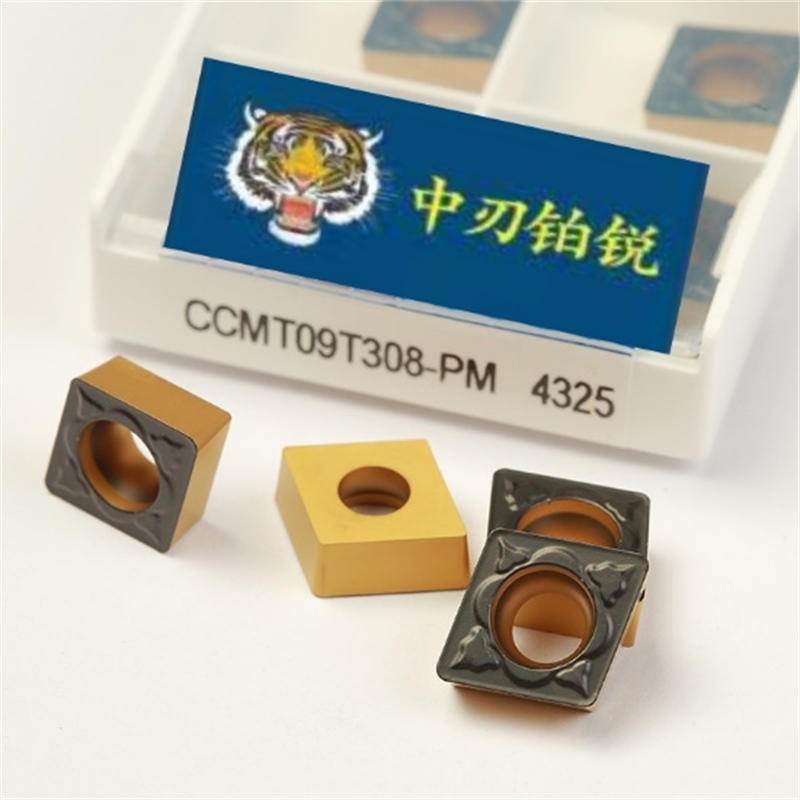

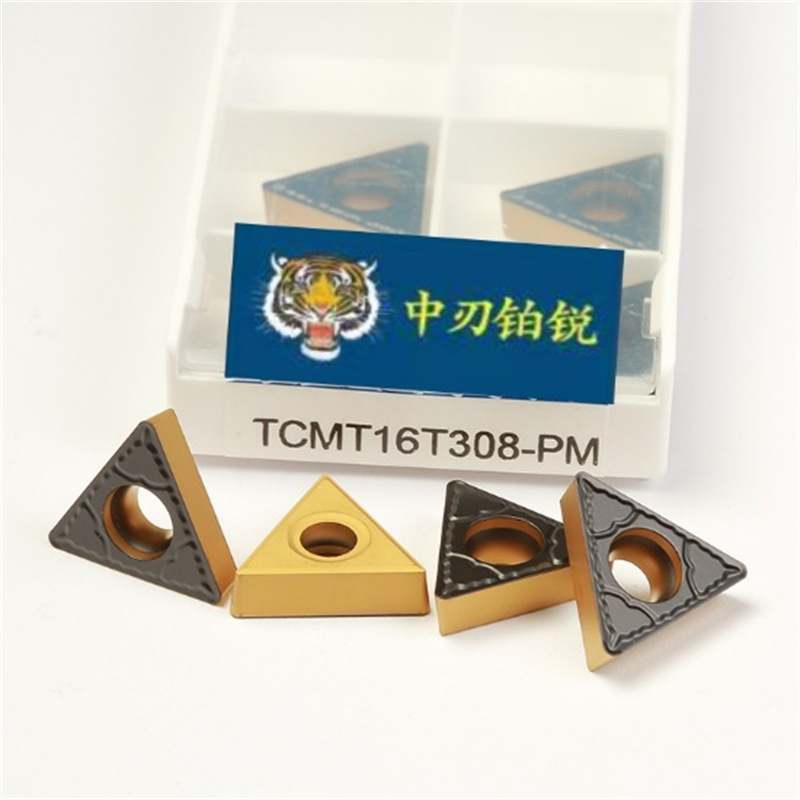

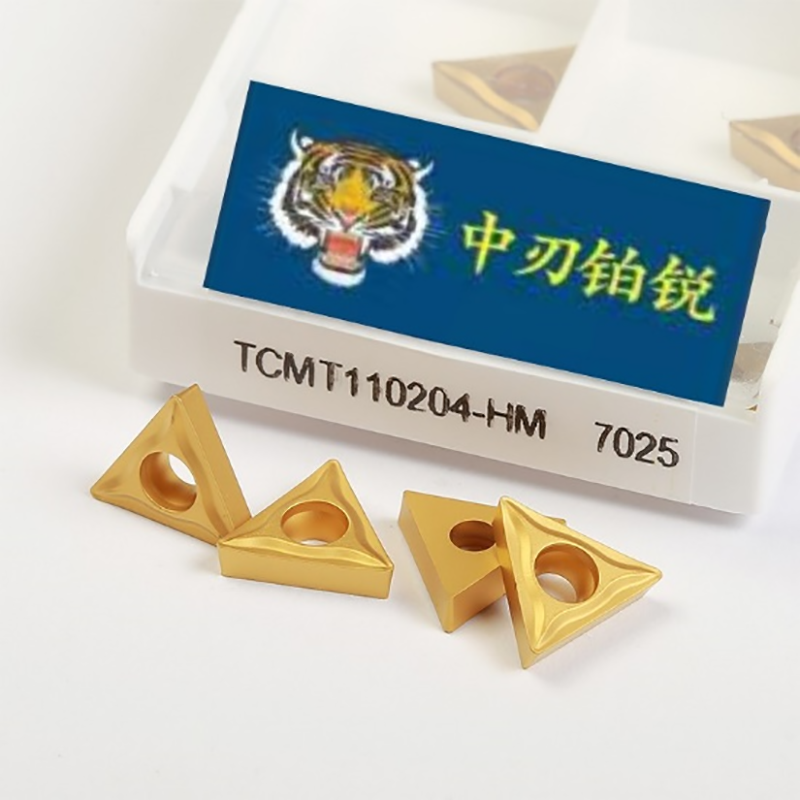

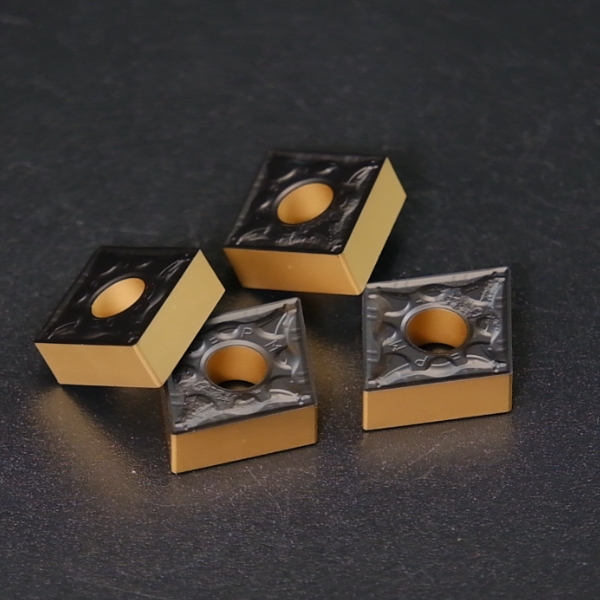

Factory Sale Tungsten Carbide Insert Milling Cutter Turning tools TCMT110204

Mofuta

Lisebelisoa tsa 1.Tungsten carbide bakeng sa Ho fetola lisebelisoa

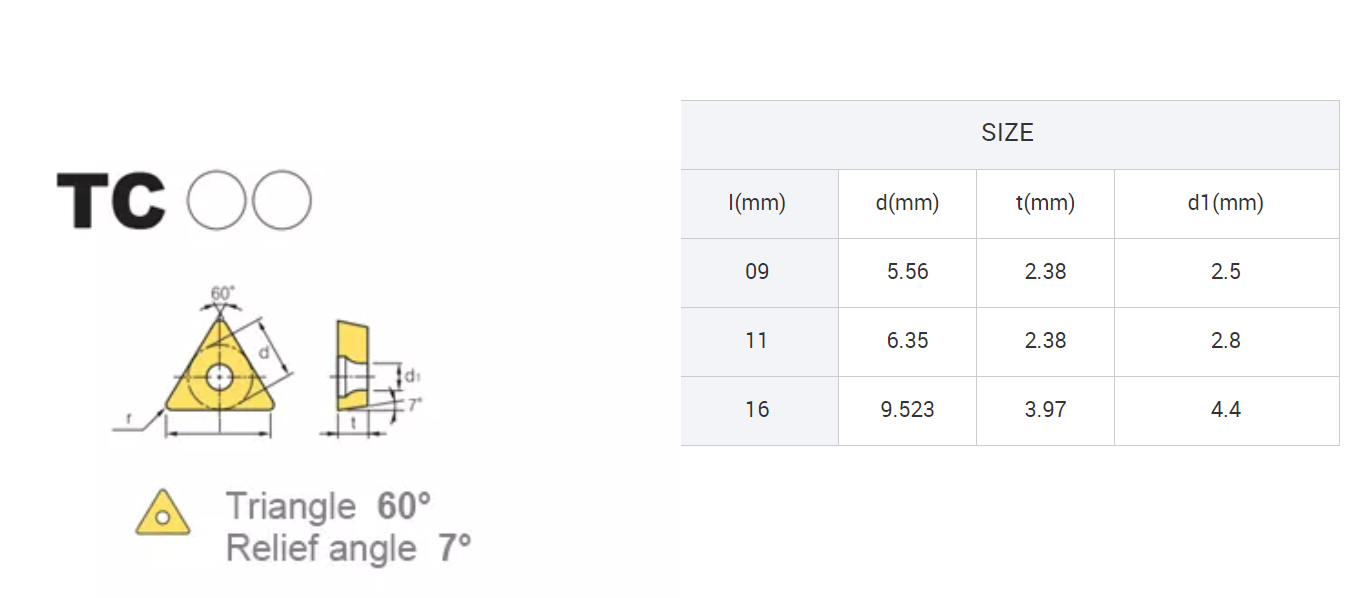

CNMG/TNMG/WNMG/DNMG/SNMG/VNMG/CCMT/DCMT/SCMT/TCMT/VBMT/KNUX

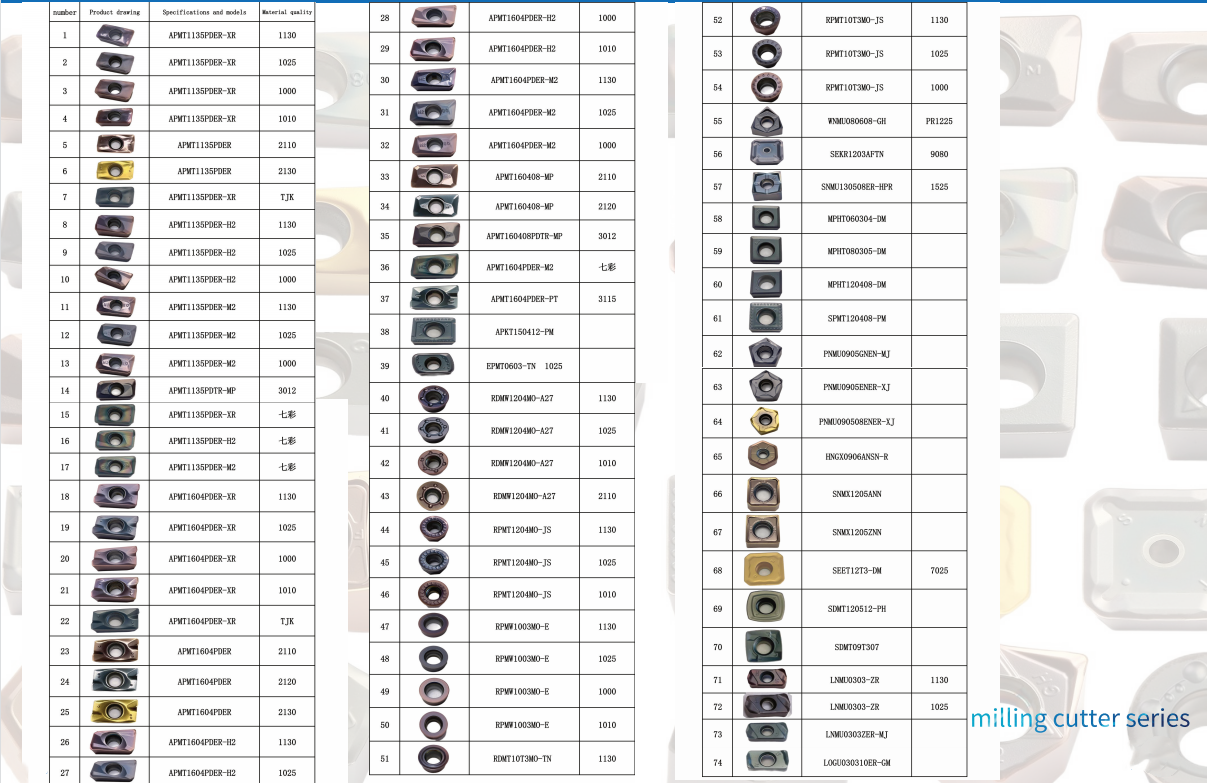

Lisebelisoa tsa 2.Tungsten carbide bakeng sa ho kenya li-milling

APKT/APMT/RPKW/RDKW/RCMT/SPKN/TPKN

Lisebelisoa tsa 3.Tungsten carbide bakeng sa Aluminium e kenya ho itšeha

CCGT/DCGX/SCGX/TCGX/VCGX

4.PCD & PCBN Tungsten carbide lisebelisoa ho fetola bakeng sa ho kenya

CNGA/DNGA/SNGA/TNGA/VNGA/CCGW/DCGW/TCGW/VBGW

Kopo e ka Sehloohong

E loketse bakeng sa semi-finishing to coarse steel processing.E loketse tšepe le tšepe e sa hloekang.201, 304, 316, 316L thepa ea tšepe e sa hloekang.

Mochini oa ho Kopo: Mochini oa ho thinya ka mahlakoreng oa mochini o phetholang thaole ea thaole

Mochini o otlolohileng oa lathe

CAM mofuta oa Switzerland lathe machining

Ho fetola mochini o sebetsang

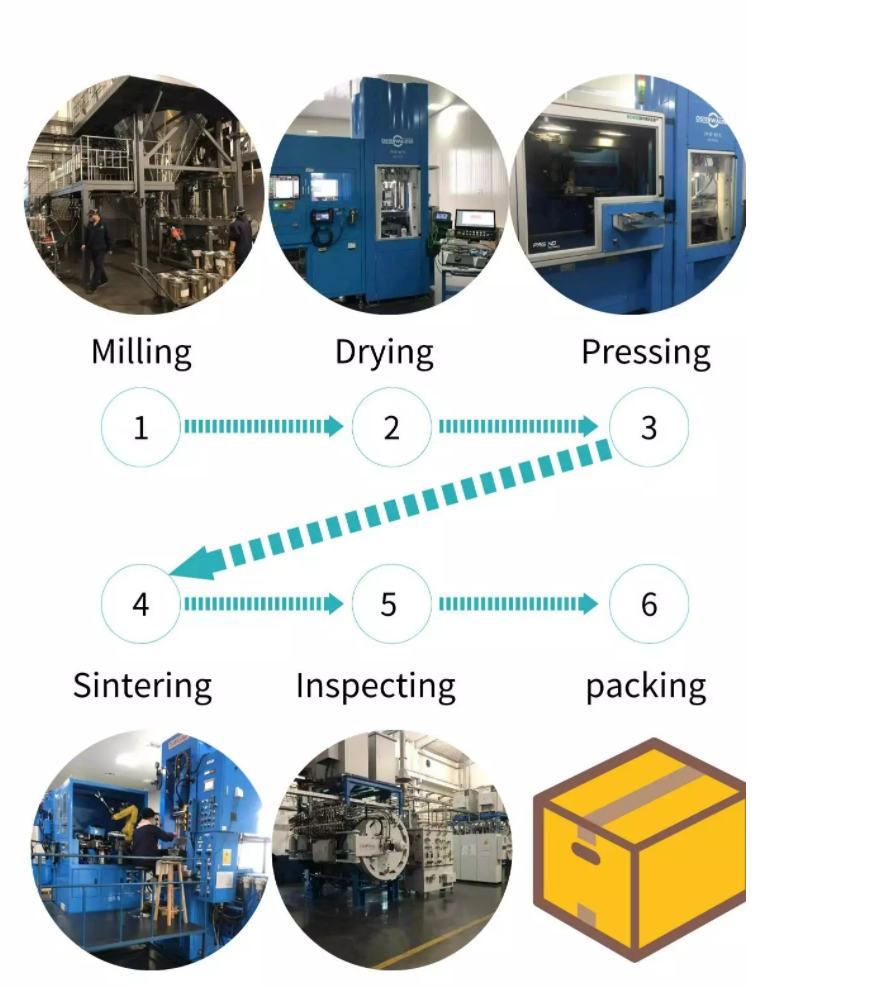

Mokhoa oa tlhahiso

Material Grade Kenyelletso

Kenyelletso ea lintho tse fetohang:

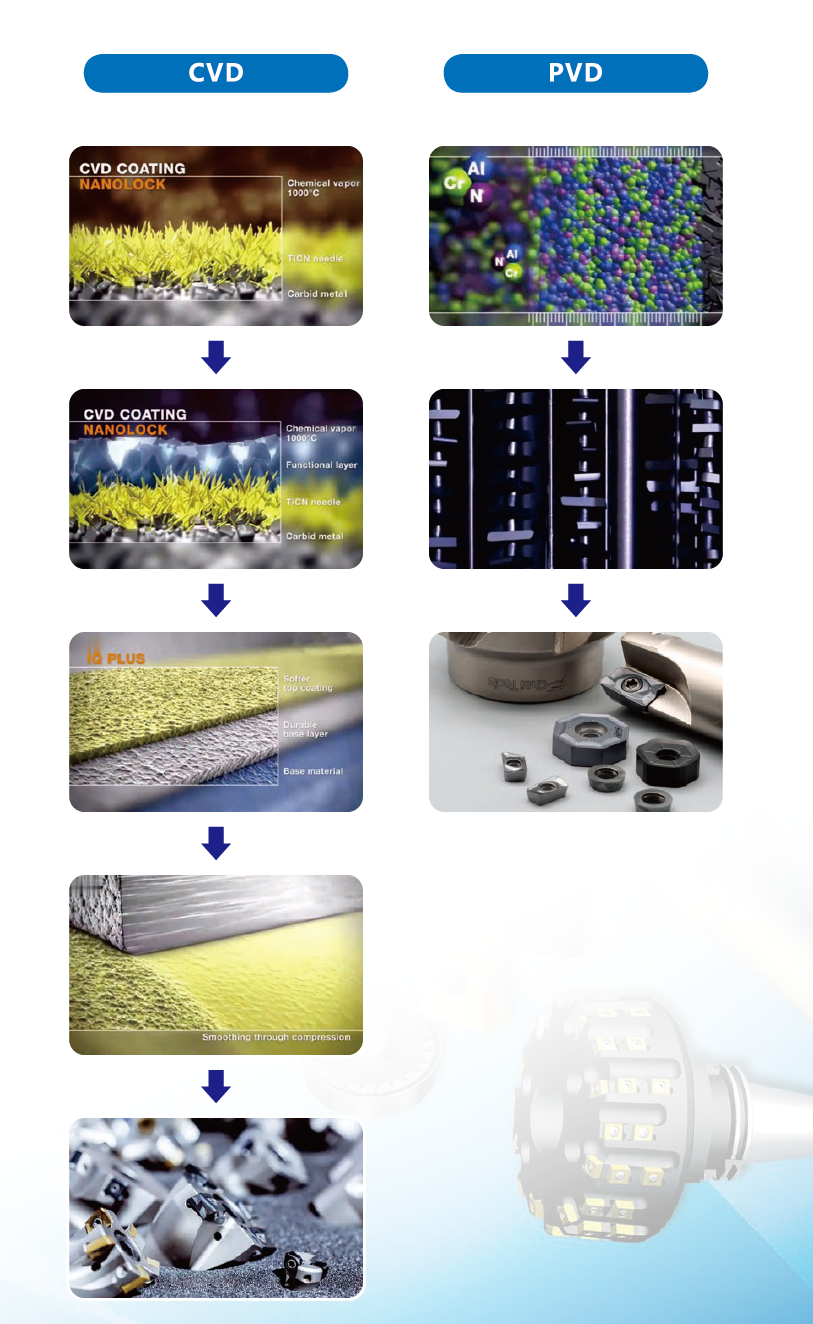

7215 e na le matla a phahameng le ho tiea ha matrix a chefo e phahameng, e kopantsoeng le MT-TICN, AL2O3, TIN e kopantsoeng hantle ea ts'ebetso ea ho roala, 'me ka mor'a ho koaheloa ka mor'a kalafo ho felisa khatello ea ka hare ea lehare la lehare, le loketseng ho qeta tšepe e tloaelehileng.

Tšireletseho ea 7125 ea matla a phahameng, boima bo phahameng ba matrix bo kopantsoeng le MT-TICN le ts'ebetso ea ho roala ea superfriction AL203, ebe ka mokhoa o tsoetseng pele oa ho roala ka mor'a phekolo ho felisa khatello ea ka hare ea ho roala, e loketseng ts'ebetso e tloaelehileng ea tšepe, ho qeta halofo le karolo ea litlhoko tsa workpiece roughness ha ba phahameng ho qeta.

4025 high corrosion resistance, le ka ts'ebetso e itseng ea khatello ea khatello ea matrix a matla a phahameng le MT-TICN le motsoako o motle haholo oa AL2O3 oa ho roala, o nang le theknoloji e tsoetseng pele ea ho roala ka mor'a kalafo ho fumana bokaholimo bo boreleli, bo loketseng mochini o thata, o qetang halofo. le ho qeta tšepe e entsoeng ka tšepe.

1030 lijo-thollo tse ntle, khanyetso e ntle ea deformation le ka ts'ebetso ea sintering ea khatello ea ho fumana matla a holimo-limo le matrix a ho hanyetsa, ka mokhoa oa ho roala ka nano PVD, ebe ka mor'a kalafo e tsoetseng pele ea ho roala ho fumana bokaholimo bo boreleli, bo loketseng ho phethela tšepe e tloaelehileng, quenched steel, chromium plated steel and stainless steel semi-finishing and finishing.

1120 lijo-thollo tse ntle haholo, khanyetso e ntle ea deformation, le ka ts'ebetso ea sintering ea khatello ho fumana matla a phahameng le ho roala matrix, e nang le nano SI e nang le ts'ebetso ea ho roala ea PVD, kamora ho koaheloa ka morao ho kalafo ho fumana bokaholimo bo boreleli.E loketse bakeng sa grooving le ho itšeha ka tšepe e tloaelehileng, tšepe e thata le tšepe e entsoeng ka tšepe.

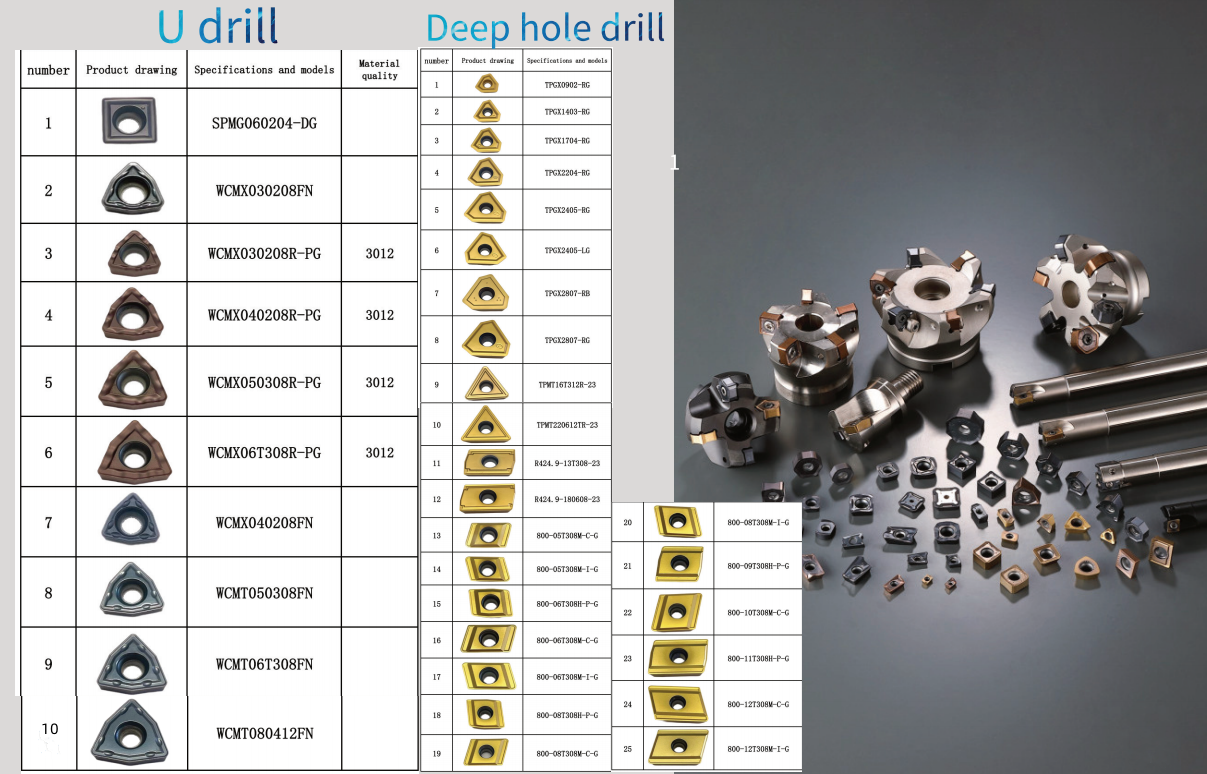

Kenyelletso ea lisebelisoa tsa ho sila le ho cheka

Ho roala ha 1030 NC-TIALN ho kopantsoe le matrix a matla le a ductile a likaroloana tse ntle li loketse ho sila mahoashe le ho qeta mefuta eohle ea thepa e entsoeng.Ho phunya, ho seha le ho phunya ha halofo ea aperture.

1130 NC-TIALN coating e nang le SI e kopantsoe le likaroloana tse ntle le boima bo botle ba matrix a alloy alloy, a loketseng tšepe e sa hloekang, karolo ea tšepe e entsoeng ka tšepe le ho qeta ho sebetsa, ho finyella motsoako o phethahetseng oa polokeho le ho hanyetsa ho apara.

5035 e kenyellelitse ho roala le likarolo tse phahameng tsa ho hanyetsa mocheso oa ho roala ha CVD, boima bo phahameng ba ho roala le ho hanyetsa mocheso o phahameng haholo ho fana ka tšireletso e sebetsang bakeng sa ho itšeha, theknoloji e khethehileng ea phekolo ea ho roala, ho roala le matrix ka mokhoa o tiileng, o loketseng mocheso o phahameng oa mocheso, lisebelisoa tsa titanium alloy ho nepahala. ts'ebetso ea ho sila.

5135 NC-TIALN coating e nang le SI e kopantsoeng le matrix ea carbide e nang le ts'ebetso e matla haholo, e loketseng likarolo tsa tšepe, tšepe e sa hloekang, grooving, seha se tebileng, ho fepa ka potlako le ho cheka ho hoholo ha metsi.

Litlhaloso tsa Sehlahisoa

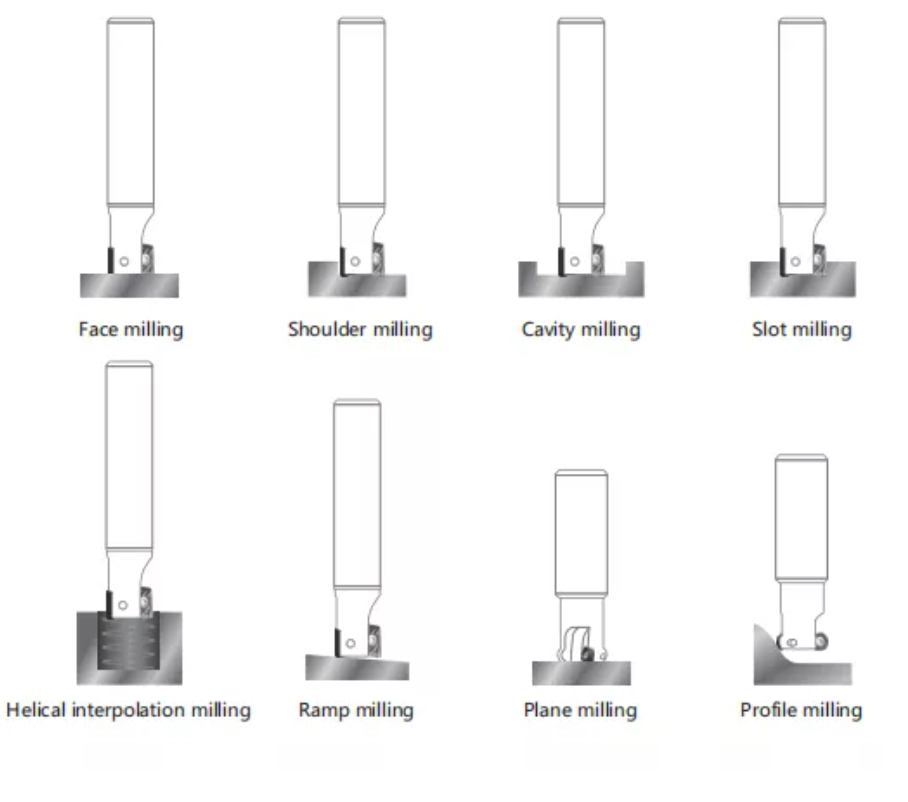

Hore na o hloka ho siloa ka kakaretso kapa ho kenya li-milling tse boima bakeng sa ho sila sefahleho, ho sila ka mahetla, sloth milling, profil milling, kapa ramp milling, kapa esita le litlhoko tse phahameng tsa ho sila holimo, Moenjiniere oa rona a ka fetola moralo oa hau hore e be mochini o kenang ka matsatsi a seng makae.

TS'ELISO PONTS'O

PHAKENG LE THUSO

100% sephutheloana se khahlanong le metsi.

Pepe ea polasetiki e le 'ngoe e paka sengoathoana se le seng, li-pcs tse 10 ka sehlopha.

Kenya thepa e kentsoeng ka pampiri ea bubble ea moea ka lebokoseng.

Sephutheloana se seng se amoheloa ho latela tlhoko ea moreki.

Litaelo li sebetsoa ka nako ka mor'a netefatso ea tefo.re na le mekhoa e mengata ea ho romella, joalo ka DHL, Fedex, EMS joalo-joalo, e tla u khethela e ntle ka ho fetisisa.

Melemo

1. Lisebelisoa tsohle tse tala li lekoa ho latela boima, boima le TRS pele li sebelisoa.

2. Karolo e 'ngoe le e' ngoe ea sehlahisoa e feta nakong ea ts'ebetso le tlhahlobo ea ho qetela.

3. Sehlopha se seng le se seng sa sehlahisoa se ka saloa morao.

Malebela a ho reka

1.Picture : Setšoantšo se bontšang lebenkeleng la rona se nkiloe lihlahisoa tsa 'nete.Ka lebaka la boemo bo fapaneng ba leseli kapa khamera

bothata, haeba 'mala oa ho paka o fapane hanyane, hoo e ka ba ntho e tloaelehileng.

2.Payment : Re amohela tefo ka ESCROW.Likarete tsa Mokitlane, T/T, West Union le Paypal Haeba u na le bothata ba ho lefa, ka kopo ikopanye le rona kapele.

3.Refund :100% Chelete ea Tšireletso ea Chelete nthong ka 'ngoe Ka kopo ikopanye le rona pele ho lihora tsa 24 ha u fumana ntho eo.Ho tla buseletsoa chelete

haeba ntho (li)lintho li se joalo ka ha li hlalositsoe 'me hang ha ntho (li)e khutliselitsoe boemong ba pele.

4.Delivery :Ka leoatle, ka moea kapa ka courer e tobileng.

5.Feedback : Khotsofalo ea hau le maikutlo a hau a nepahetseng ke tsa bohlokoa haholo ho rona.Ka kopo siea maikutlo a nepahetseng le linaleli tse 5 haeba u khotsofetse

ka thepa le litšebeletso tsa rona.

Haeba u na le mathata ka thepa kapa litšebeletso tsa rona, ka kopo ikutloe u lokolohile ho ikopanya le rona pele u siea maikutlo a fosahetseng.Rona

e tla rarolla mathata kapele mme e u tšepise lihlahisoa le lits'ebeletso tse ntle tsa 100%.

Khothatso ea hau le ts'ehetso ea hau ke ts'ebetso ea rona e tsoelang pele.

Litifikeiti

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC