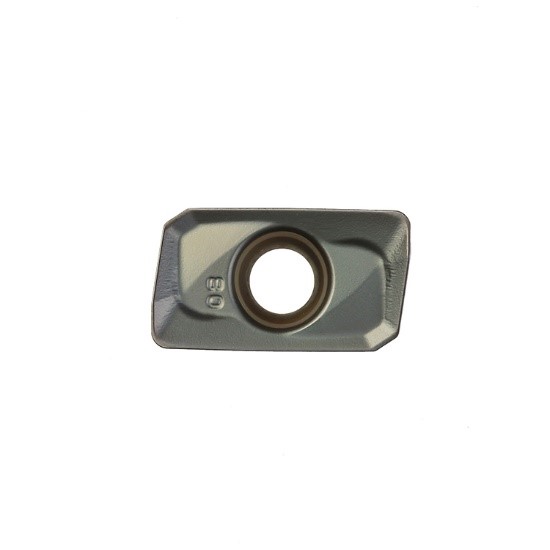

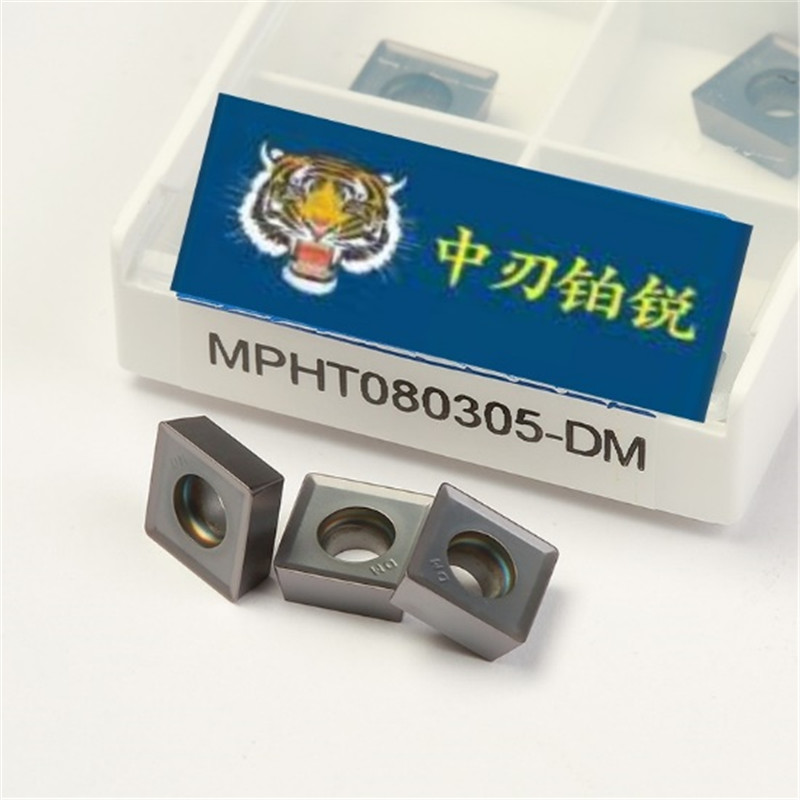

Tungsten Carbide Milling Insets Apmt1135pder 1130 lisebelisoa tsa ho itšeha

Tlhaloso e Khutšoane

Tungsten Carbide Cutting Insert e nang le libopeho tse fapaneng le lisebelisoa bakeng sa sepheo se fapaneng sa ho itšeha le ka khanyetso e phahameng ea ho roala e leng phetisetso e ntle ea ho kenya ceramic, ho kenya koae le ho kenya alloy.E loketse lisebelisoa tsa motsoako o chesang bakeng sa ho nchafatsa holim'a metsi le ho etsa hore ho khonehe ho fana ka liphahlo tse felletseng ho matlafatsa ho hanyetsa mocheso, ho hanyetsa mocheso, ho hanyetsa kutu le ho hanyetsa ts'ebetso ea tšireletso ea holim'a metsi le liphahlo tse khethehileng tsa ho tiisa, ho kenya letsoho le super-conduction.

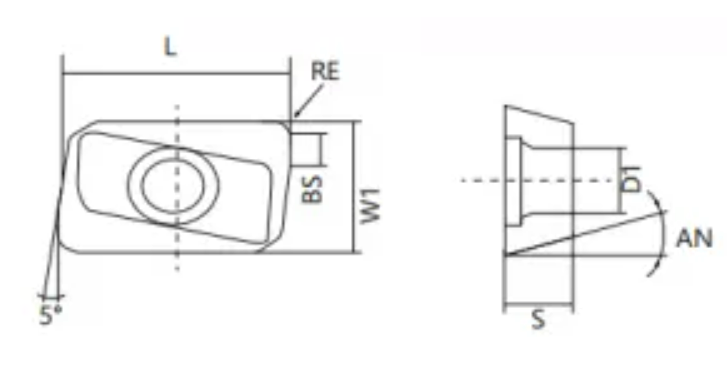

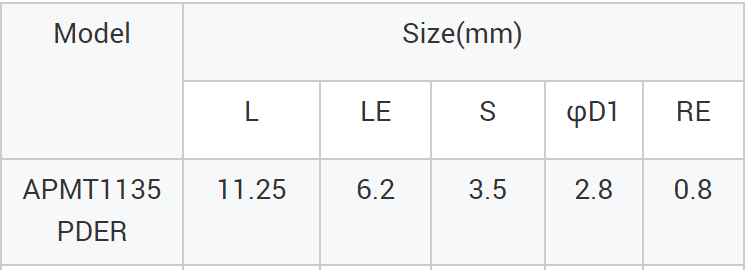

Litlhaloso tsa Sehlahisoa

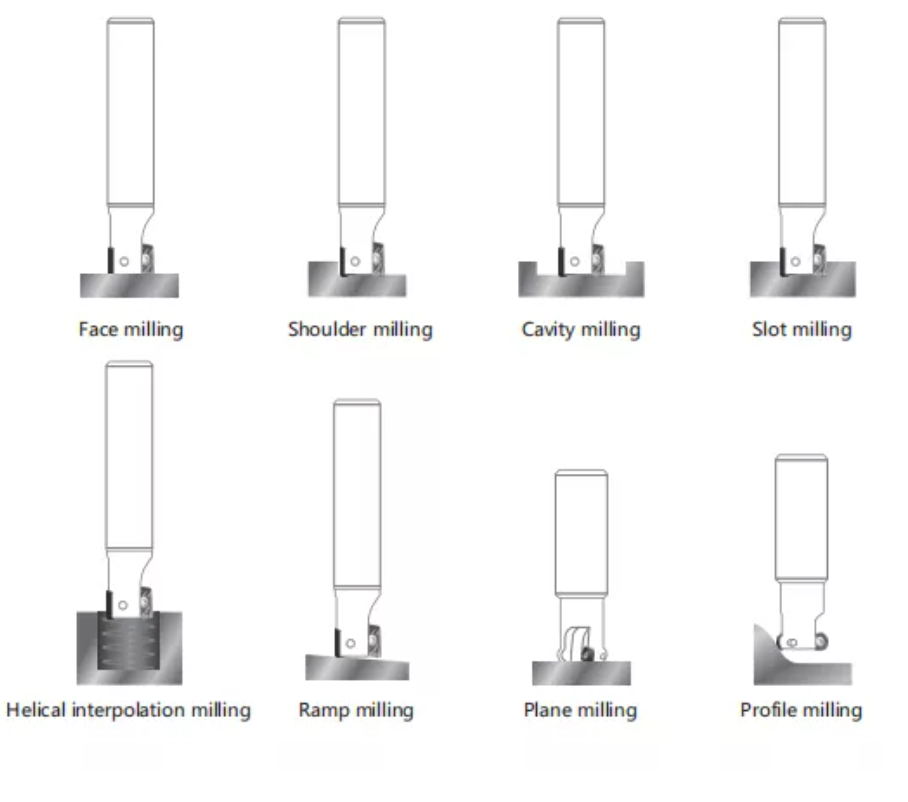

Hore na o hloka ho siloa ka kakaretso kapa ho kenya li-milling tse boima bakeng sa ho sila sefahleho, ho sila ka mahetla, sloth milling, profil milling, kapa ramp milling, kapa esita le litlhoko tse phahameng tsa ho sila holimo, Moenjiniere oa rona a ka fetola moralo oa hau hore e be mochini o kenang ka matsatsi a seng makae.

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

Litifikeiti

Melemo

1. Ho rarolloa ka katleho ho haha mosebetsi o thata le mathata a mang a machining.

2. Sekhahla se bohale, matla a manyenyane a ho itšeha.

3. Molemo machining holim boleng.

4. Excellent sesebelisoa bophelo nako.

5. Liodara tse nyenyane li amoheleha bakeng sa ho tsamaisoa ka potlako le ho u thusa ho fokotsa litšenyehelo tsa thepa.

Likaroloana

1. Ho rarolloa ka katleho ho haha mosebetsi o thata le mathata a mang a machining.

2. Sekhahla se bohale, matla a manyenyane a ho itšeha.

3. Molemo machining holim boleng.

4. Excellent sesebelisoa bophelo nako.

5. Liodara tse nyenyane li amoheleha bakeng sa ho tsamaisoa ka potlako le ho u thusa ho fokotsa litšenyehelo tsa thepa.