Malebela ka Mechini ea ho Tula APMT1135PDER CNC Cutting Tools Turning Blade Indexable Lathe Cutter Coated Milling Insert

Tlhaloso ea Sehlahisoa

Lisebelisoa tsa carbide li lokela ho cheselletsoa holim'a sets'oants'o, se sebelisoang holim'a lathe bakeng sa ho lokisa lisebelisoa tse fapaneng tse kang tšepe e entsoeng ka tšepe, tšepe, tšepe e sa hloekang, tšepe e sa tsitsang, joalo-joalo. ;machining ea likarolo tsa eccentric joalo ka li-gearbox casings, le likopano tsa molumo o phahameng, haholo litsing tsa machining le likarolo tse potolohang ka lilathe.Tungsten Carbide Cutting Insert e nang le libopeho tse fapaneng le lisebelisoa bakeng sa sepheo se fapaneng sa ho itšeha le ka khanyetso e phahameng ea ho roala e leng phetisetso e ntle ea ho kenya ceramic, ho kenya koae le ho kenya alloy.E loketse lisebelisoa tsa motsoako o chesang bakeng sa ho nchafatsa holim'a metsi le ho etsa hore ho khonehe ho fana ka liphahlo tse felletseng ho matlafatsa ho hanyetsa mocheso, ho hanyetsa mocheso, ho hanyetsa kutu le ho hanyetsa ts'ebetso ea tšireletso ea holim'a metsi le liphahlo tse khethehileng tsa ho tiisa, ho kenya letsoho le super-conduction.

Lisebelisoa tsa Carbide APMT PVD tse koahetsoeng hangata li sebelisoa bakeng sa li-cutters tsa ho qetela tsa lisekoere tsa mahetla le li-cutter tsa sefahleho.Lisebelisoa tsa APMT li na le IC e entsoeng ka mokhoa o nepahetseng, e nang le chip breaker e ntle.Li na le moeli o bohale le o nang le bohloeki le sekhutlo sa 11 ° sa liphallelo.Li na le masoba a screw a entsoeng ho latela ISO.Ka tloaelo, e talingoa joalo ka lithapo tse 2 tsa ho itšeha.Leha ho le joalo, li na le likarolo tse 4 tsa ho itšeha.ha li kentsoe ho li-milling cutters tsa 90° indexable indexable cutters 'me mahlakore ka bobeli a ba lerootho, a ka kengoa ho li-milling cutters tse 75° Â 'me a tsoele pele ho sebelisa lits'ebetso tse ling ka mahlakore a mang a mabeli.APMT e tla ba khetho e ntle bakeng sa basebelisi ba ho qetela, kaha e e ka ntlafatsa haholo tlhahiso.

Kopo e ka Sehloohong

Bakeng sa ho sebetsa tšepe ea carbon, tšepe e entsoeng ka tšepe, tšepe e sa hloekang

Indasteri ea kopo

CNC ho fetola le ho sila lihlahisoa tsa lihlahisoa tsa lihlahisoa tsa tungsten carbide li sebelisoa haholo ho: Indasteri ea ho etsa likoloi, indasteri ea tlhahiso ea Mold, indasteri ea lifofane, indasteri ea ts'ireletso, indasteri ea ho sebetsa ka matla le tse ling tse ngata.

re ka hlahisa mefuta e fapaneng ea lisebelisoa tsa ho itšeha tsa tungsten carbide ho ea ka litšoantšo tse fapaneng tse hlophisitsoeng.

re ka fana ka litharollo tse tšehetsang ka kakaretso bakeng sa tšimo ea machining.

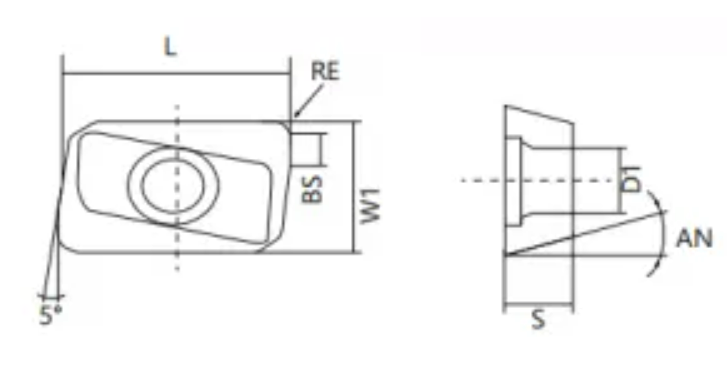

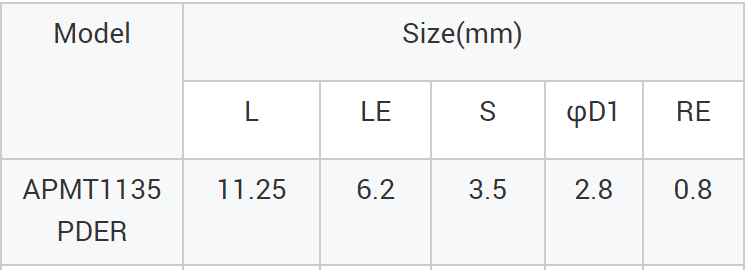

Litlhaloso tsa Sehlahisoa

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

Litifikeiti

Melemo

1. Ho rarolloa ka katleho ho haha mosebetsi o thata le mathata a mang a machining.

2. Sekhahla se bohale, matla a manyenyane a ho itšeha.

3. Molemo machining holim boleng.

4. Excellent sesebelisoa bophelo nako.

5. Liodara tse nyenyane li amoheleha bakeng sa ho tsamaisoa ka potlako le ho u thusa ho fokotsa litšenyehelo tsa thepa.

Likaroloana

1. Ho hanyetsa ho apara ka mokhoa o babatsehang, boima bo botle bo chesang, ho ntlafatsa katleho ea Tlhahiso.

2. Sebaka se nepahetseng le se bentšitsoeng, se nang le phello e phethahetseng ea ho itšeha

3. Ho roala ha PVD ho netefatsa bophelo bo bolelele ba sesebelisoa.

4. E ka tsamaisana le boholo ba lisebelisoa tsa mofuta oa brand / sets'oants'o.