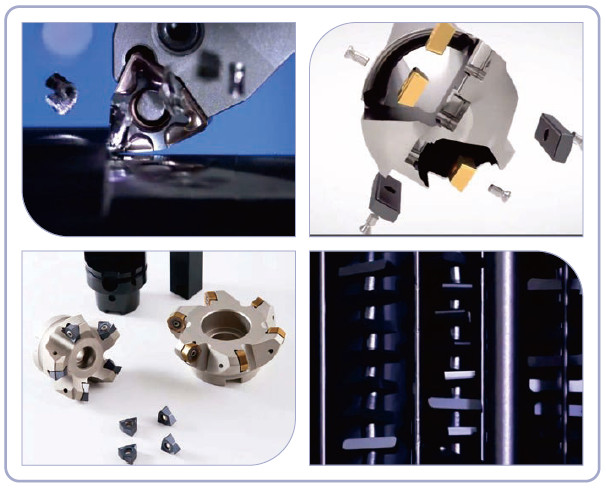

Ts'ebetso ea ho itšeha e nka karolo ea 90% ea mosebetsi oa machining.Sesebelisoa ke "leino" la mochine oa mochine oa indasteri, o amang ka ho toba boemo ba ts'ebetso ea indasteri ea tlhahiso.Ho itšeha ho bolela ho khaola lisebelisoa tse feteletseng ho tloha holim'a workpiece, ho etsa bonnete ba hore geometry ea mosebetsi, ho nepahala ha dimensional, boleng ba holim'a metsi le likarolo tse ling tsa litlhoko tsa moralo oa mokhoa oa machining, tse ikarabellang bakeng sa hoo e ka bang 90% ea mosebetsi oohle oa machining.Ho itšeha hangata ho finyelloa ka ho itšeha lisebelisoa tsa mochine, 'me sesebelisoa ke ntho e ka sehloohong e ka sebelisoang, e le "meno" a lisebelisoa tsa mochine oa indasteri, boleng ba eona bo ama ka ho toba tlhahiso ea boemo ba theknoloji ea tlhahiso ea mechine, katleho ea tlhahiso le boleng ba sehlahisoa.Lisebelisoa tsa ho itšeha ho ea holimo bakeng sa barekisi ba thepa e tala, tse sebelisoang liindastering tse kholo tsa tlhahiso.Nka ka ho fetisisa ka sehloohong carbide sesebelisoa e le mohlala, ho ea ka thepa sebetswa ka aroloa ka: tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe, tšepe non-ferrous, mocheso manganga motsoako, tšepe e thata, joalo-joalo Upstream bakeng sa thepa e tala e tšoanang () tungsten carbide, cobalt powder, tantalum niobium solid solution, joalo-joalo) bahlahisi, sebaka sa kopo se tlase se tsepamisitsoe indastering ea tlhahiso, e sebelisoang haholo ho likoloi le lithuthuthu, lisebelisoa tsa mochini, mochini o akaretsang, hlobo, metjhini ea boenjiniere le masimo a mang, sefofane, sesole, mechine ea bongaka le masimo a mang le tsona li fana ka ts'ebeliso e pharaletseng ea tekheniki le sebaka sa phetoho bakeng sa lisebelisoa tsa carbide.

Litšobotsi tsa lisebelisoa tsa ho itšeha carbide ke life?

1. boima bo phahameng: Sesebelisoa sa carbide se entsoe ka carbide e nang le boima bo phahameng le ntlha ea ho qhibiliha (e tsejoang e le karolo e thata) le tšepe ea tšepe (e tsejoang e le karolo e tlamang) ka mokhoa oa metallurgy oa phofo, boima ba eona ke 89 ~ 93HRA, e phahameng haholo ho feta tšepe e potlakileng. , ho 5400C, boima bo ntse bo ka fihla ho 82 ~ 87HRA, le boima bo phahameng ba mocheso oa mocheso oa tšepe (83 ~ 86HRA) bo tšoanang.

2. Matla a ho kobeha le ho tiea: matla a kobehang a motsoako o thata o tloaelehileng o maemong a 900 ~ 1500MPa.The diteng tse phahameng tsa tšepe e tlamang mohato, e phahameng matla a kobehang.Ha litaba tsa binder li tšoana, YG(WC-Co).Matla a alloy a phahame ho feta YT (WC-Tic-Co) alloy, 'me matla a fokotseha ka ho eketseha ha litaba tsa TiC.Alloy e thata ke mofuta oa thepa e brittle, ho tiea ha eona mochesong oa kamore ke 1/30 ~ 1/8 feela ea HSS.

3. Ho hanyetsa ho apara hantle.Lebelo la ho itšeha la sesebelisoa sa carbide ke makhetlo a 4 ~ 7 ho feta a tšepe ea lebelo le phahameng, 'me bophelo ba sesebelisoa bo phahame ka makhetlo a 5 ~ 80.Ho etsa hlobo, lisebelisoa tsa ho lekanya, bophelo ho feta tšepe ea alloy 20 ~ 150 linako tse phahameng.E ka khaola 50HRC kapa thepa e thata haholo.

Nako ea poso: Dec-29-2022