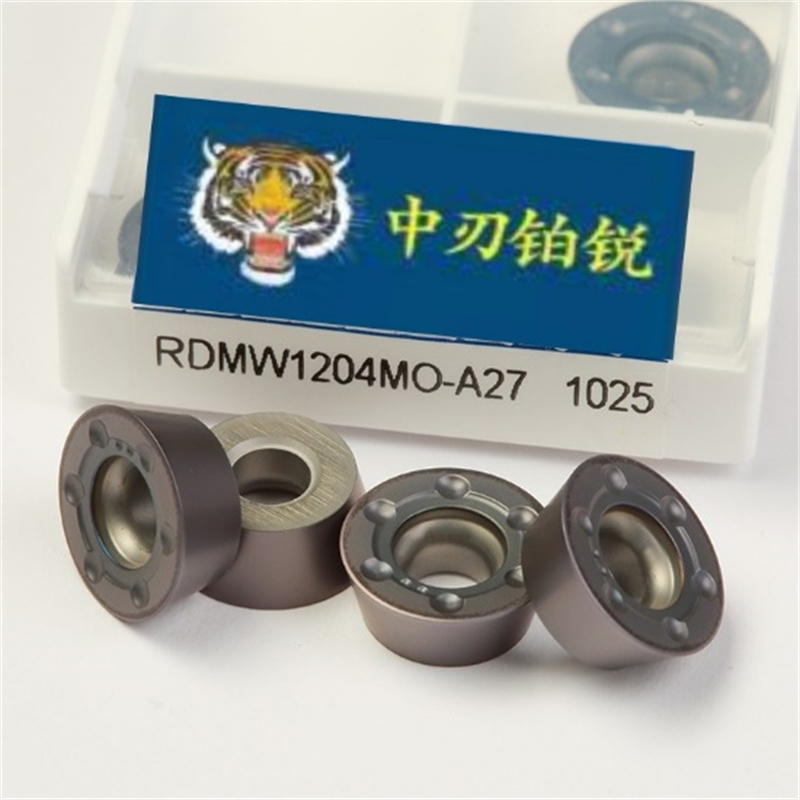

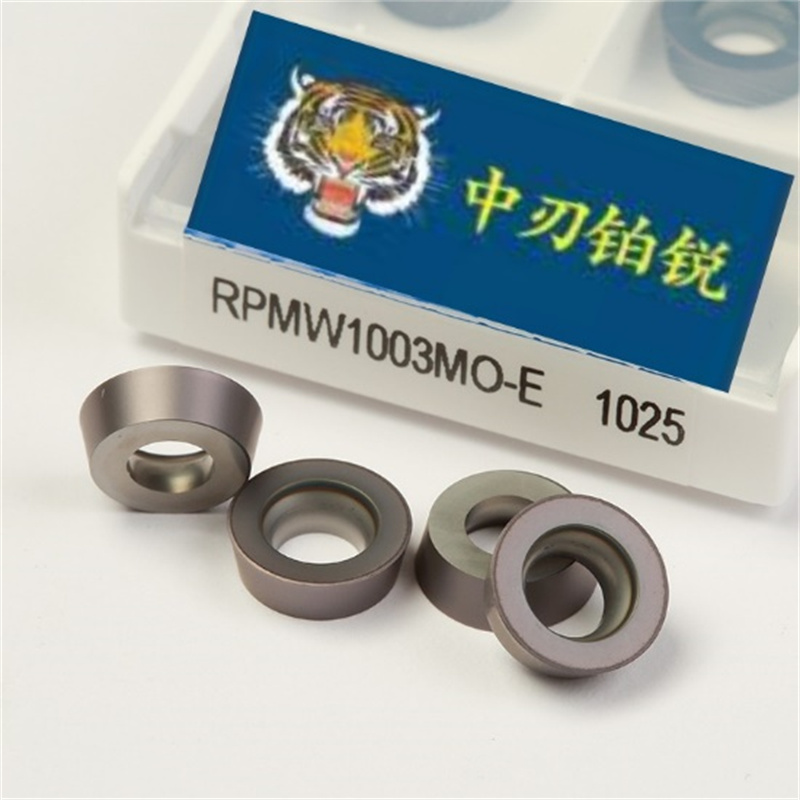

RDMW1204 carbide e kenya indexable Milling Insert carbide cutting tools for HRC50 HRC60

Litaba tsa Motheo

Ho boima bo fapaneng ba lisebelisoa tsa hlobo, re ka lekola bophelo ba lisebelisoa tsa ho seha ka nepo.Mosebetsi oa ho sila ka tšepe kapa tšepe e sa hloekang kapa tšepe e entsoeng ka tšepe kapa alloy alloy, lisebelisoa tsa rona tsa ho sila li entsoe ka mokhoa o ikhethang ka carbide ea boleng bo holimo, le theknoloji e phahameng ea AlTiN e phahameng ka ho fetesisa.Tsena li etsa hore mochini oa rona oa ho sila o be le ts'ebetso e nepahetseng ea ts'ebetso le boleng bo tsitsitseng ho isa holimo.

Kopo

Tšebeliso ea mantlha:Bakeng sa ho sebetsa tšepe ea carbon, tšepe e entsoeng ka tšepe, tšepe e sa hloekang

Indasteri ea kopo:

CNC ho fetola le ho sila lihlahisoa tsa lihlahisoa tsa lihlahisoa tsa tungsten carbide li sebelisoa haholo ho: Indasteri ea ho etsa likoloi, indasteri ea tlhahiso ea Mold, indasteri ea lifofane, indasteri ea ts'ireletso, indasteri ea ho sebetsa ka matla le tse ling tse ngata.

re ka hlahisa mefuta e fapaneng ea lisebelisoa tsa ho itšeha tsa tungsten carbide ho ea ka litšoantšo tse fapaneng tse hlophisitsoeng.

re ka fana ka litharollo tse tšehetsang ka kakaretso bakeng sa tšimo ea machining.

Litlhaloso tsa Sehlahisoa

| Mofuta | Boholo(mm) | ||

| D | S | D1 | |

| RDMW120400-PR | 12.00 | 4.76 | 4.40 |

| RDMW1204MOT-PM | 12.00 | 4.76 | 4.40 |

| RDMW1204MO-TT | 12.00 | 4.76 | 4.40 |

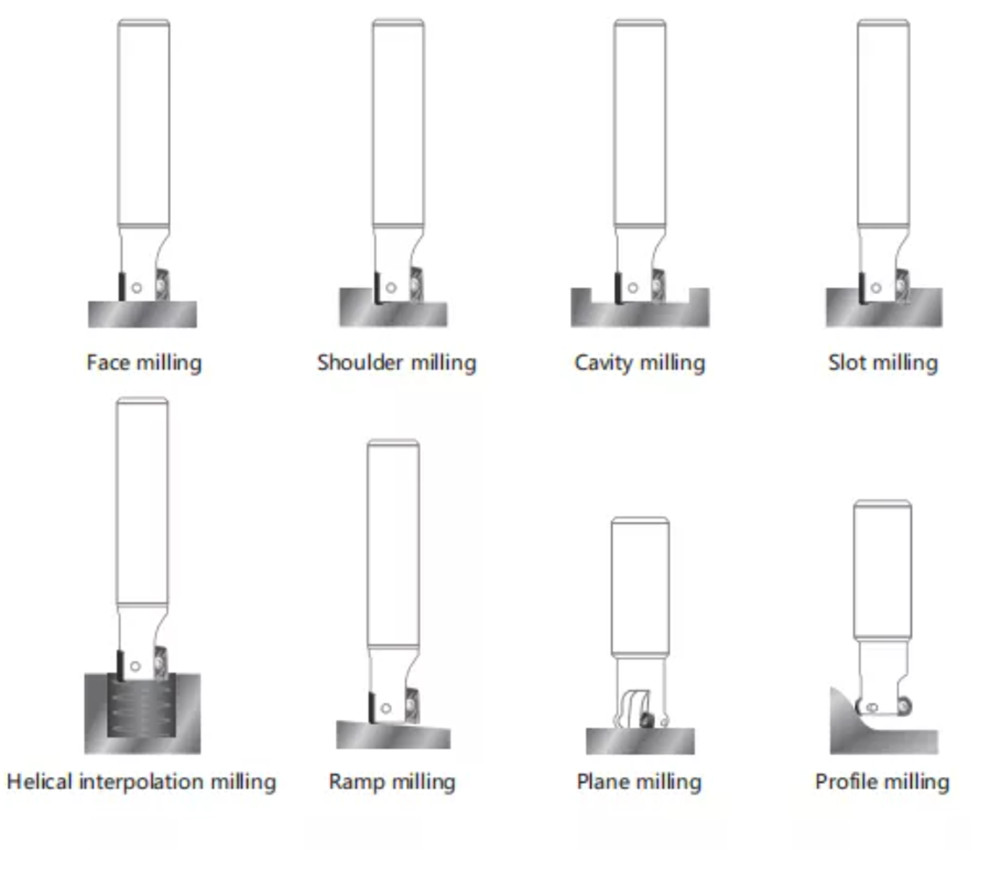

Hore na o hloka ho siloa ka kakaretso kapa ho kenya li-milling tse boima bakeng sa ho sila sefahleho, ho sila ka mahetla, sloth milling, profil milling, kapa ramp milling, kapa esita le litlhoko tse phahameng tsa ho sila holimo, Moenjiniere oa rona a ka fetola moralo oa hau hore e be mochini o kenang ka matsatsi a seng makae.

Pontšo ea ho roala

Litifikeiti

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

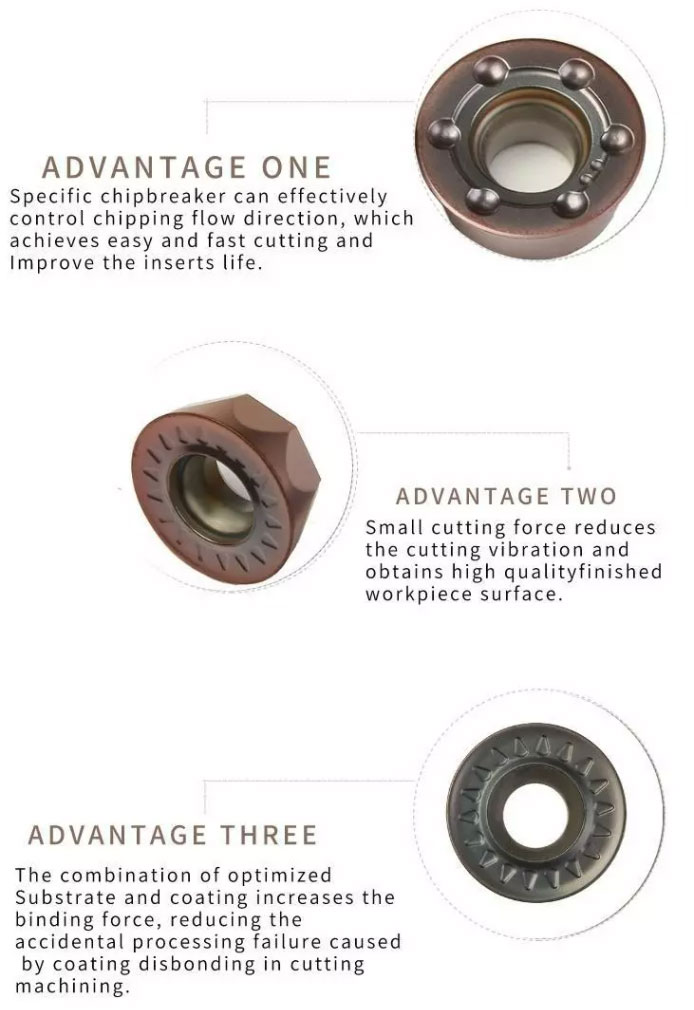

Melemo

1.Light itšeha, ho sebetsa ka thelelo;

Ts'ebetso ea 2.Anti-collapse, hape le khanyetso e ntle ea ho roala;

3.Ho sebetsa hantle haholo ha ho sila, bophelo bo bolelele ba ho itšeha.

Likaroloana

1. Molemo o chesang thata

2. E babatsehang ho apara ho hanyetsa

3. Ntlafatsa katleho ea Tlhahiso

4. Ka ho roala PVD le CVD

5. Ho roala ha Al2O3 le TiN