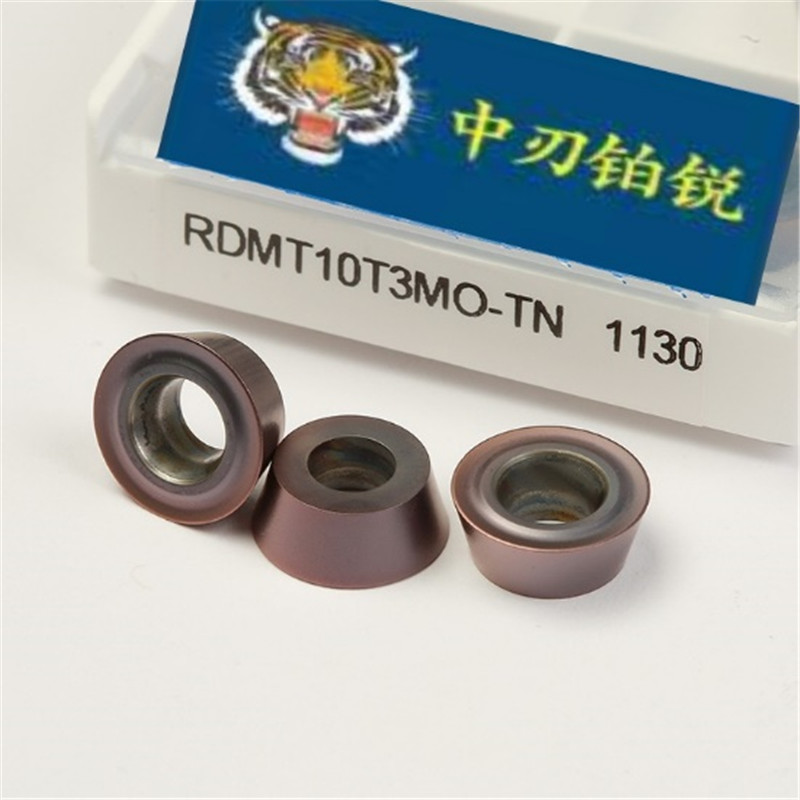

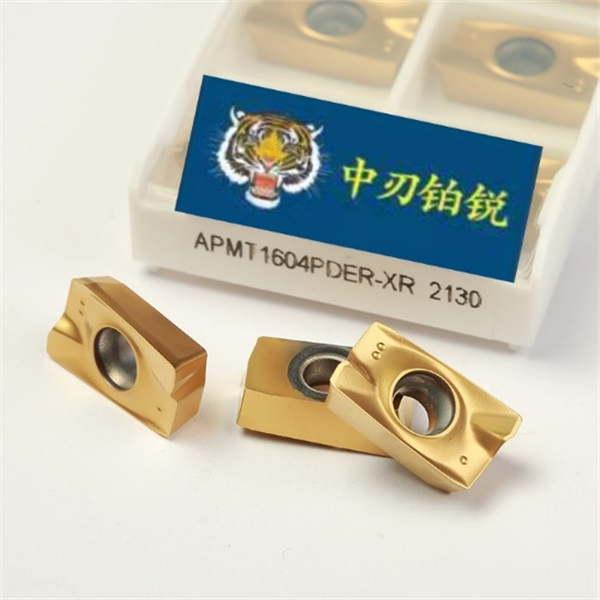

Tungsten Carbide Turning/Milling/Threading/Grooving/Drilling CNC Insert Rpmt Lnmu Machine Carbide Cutting Insets Apmt160408pder

Litaba tsa Motheo

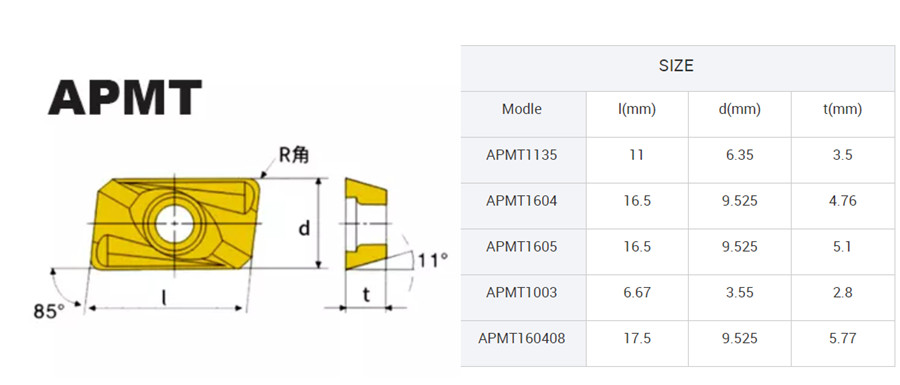

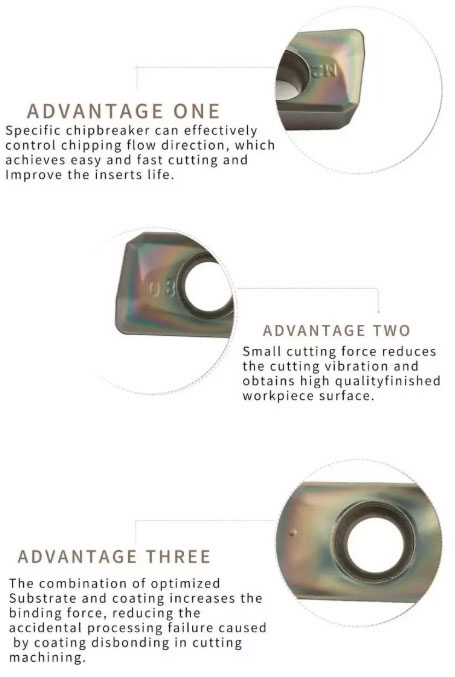

Lisebelisoa tsa Carbide APMT PVD tse koahetsoeng hangata li sebelisoa bakeng sa li-cutters tsa ho qetela tsa lisekoere tsa mahetla le li-cutter tsa sefahleho.Lisebelisoa tsa APMT li na le IC e entsoeng ka mokhoa o nepahetseng, e nang le chip breaker e ntle.Li na le moeli o bohale le o nang le bohloeki le sekhutlo sa 11 ° sa liphallelo.Li na le masoba a screw a entsoeng ho latela ISO.Ka tloaelo, e talingoa joalo ka lithapo tse 2 tsa ho itšeha.Leha ho le joalo, li na le likarolo tse 4 tsa ho itšeha.ha li kentsoe ho li-milling cutters tsa 90° indexable indexable cutters 'me mahlakore ka bobeli a ba lerootho, a ka kengoa ho li-milling cutters tse 75° Â 'me a tsoele pele ho sebelisa lits'ebetso tse ling ka mahlakore a mang a mabeli.APMT e tla ba khetho e ntle bakeng sa basebelisi ba ho qetela, kaha e e ka ntlafatsa haholo tlhahiso.

Litlhaloso tsa Sehlahisoa

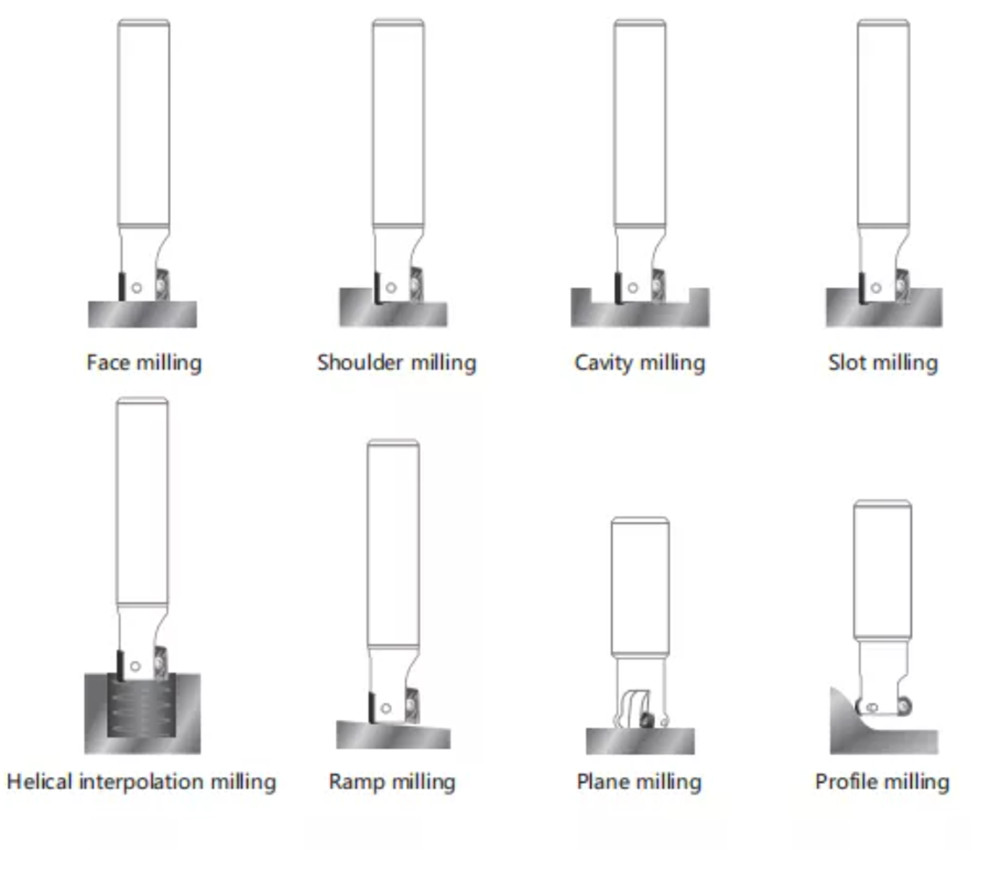

Hore na o hloka ho siloa ka kakaretso kapa ho kenya li-milling tse boima bakeng sa ho sila sefahleho, ho sila ka mahetla, sloth milling, profil milling, kapa ramp milling, kapa esita le litlhoko tse phahameng tsa ho sila holimo, Moenjiniere oa rona a ka fetola moralo oa hau hore e be mochini o kenang ka matsatsi a seng makae.

Pontšo ea ho roala

Litifikeiti

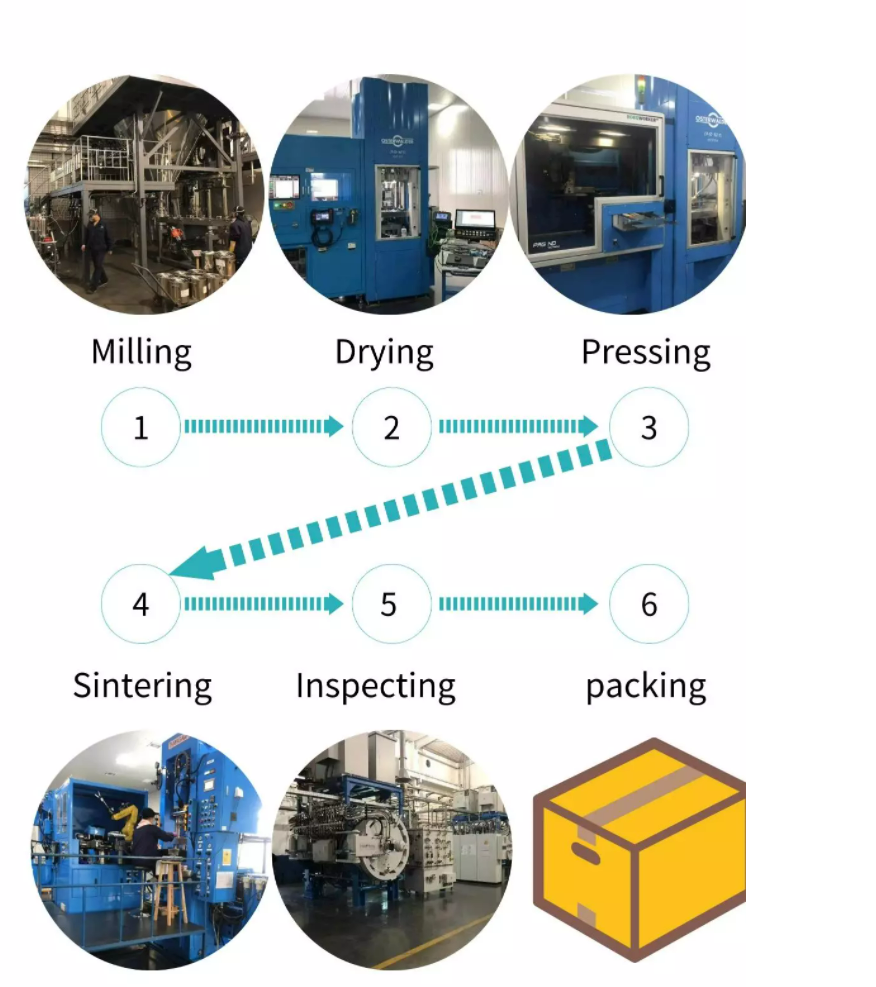

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

Melemo

1. Ho hanyetsa ho apara hantle, matla a holimo a ho kobeha, ho hanyetsa ho matla ho tlamahaneng, ho hanyetsa mocheso o babatsehang, ho tiea ha tšusumetso le boima bo phahameng.

2. Bophelo ba nako e telele ea tšebeletso le ho bokelloa habonolo, ha ho na ho phatloha kapa ho phunyeha

3. Mehlala ea mahala e fumaneha.

4. Liodara tse nyenyane li amoheleha bakeng sa ho tsamaisoa ka potlako le ho u thusa ho fokotsa litšenyehelo tsa thepa.