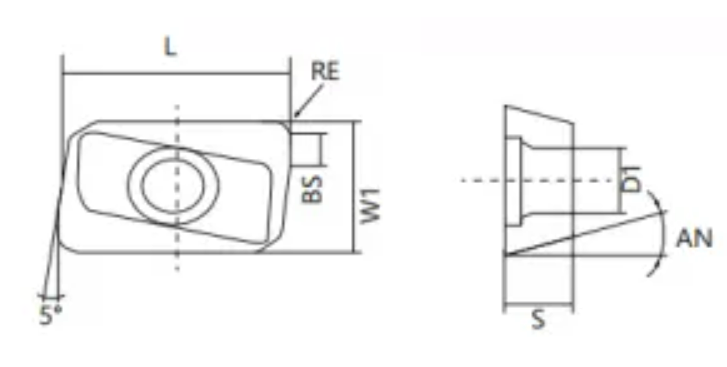

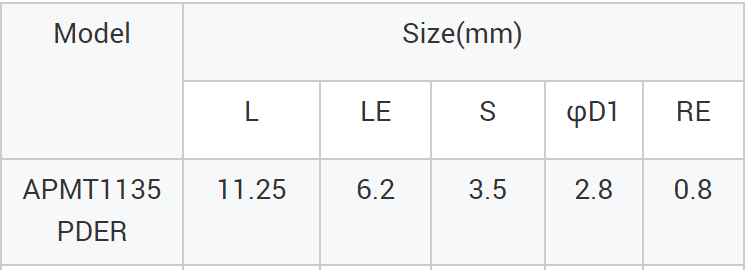

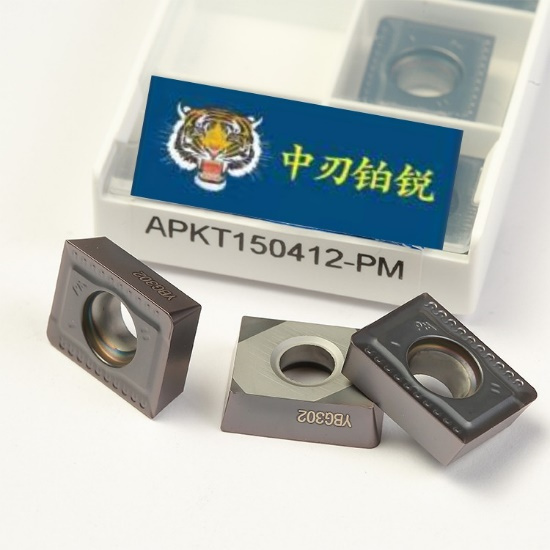

Tungsten Carbide Turning Indexable Insert APMT1135 bakeng sa amuninum/stainless steel/Cast Iron

Litaba tsa Motheo

APMT1135 ke ea square shoulder milling, e hlahisang lifahleho tse peli ka nako e le 'ngoe, e hlokang motsoako oa ho sila ka peripheral le ho sila sefahleho.Mahetla a sefahleho sa mahetla a meralo e tloaelehileng hangata a khona ho sila "'nete", mahetla a 90-degree a sa tebang.Li-mill tse ngata tsa mahetla ke li-cutters tsa bokahohleng, 'me li ka sebelisoa hamolemo bakeng sa ho etsa masoba.Ho sila ka mahetla ho ka etsoa ka litšila tse tloaelehileng tsa mahetla, li-end milling, li-milling cutters tse telele, li-milling cutters le li-face cutters tse ka sebelisoang.

Tšebeliso ea mantlha:

Bakeng sa ho sebetsa tšepe ea carbon, tšepe e entsoeng ka tšepe, tšepe e sa hloekang

Indasteri ea kopo:

CNC ho fetola le ho sila lihlahisoa tsa lihlahisoa tsa lihlahisoa tsa tungsten carbide li sebelisoa haholo ho: Indasteri ea ho etsa likoloi, indasteri ea tlhahiso ea Mold, indasteri ea lifofane, indasteri ea ts'ireletso, indasteri ea ho sebetsa ka matla le tse ling tse ngata.

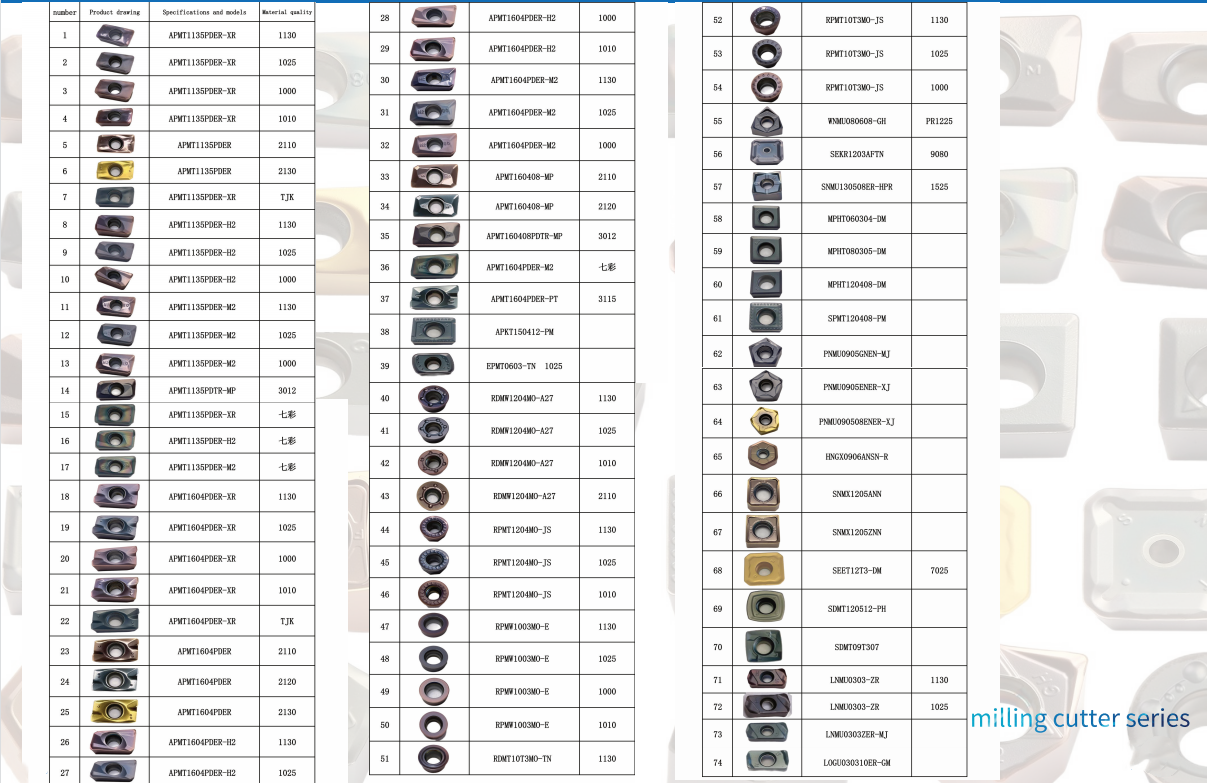

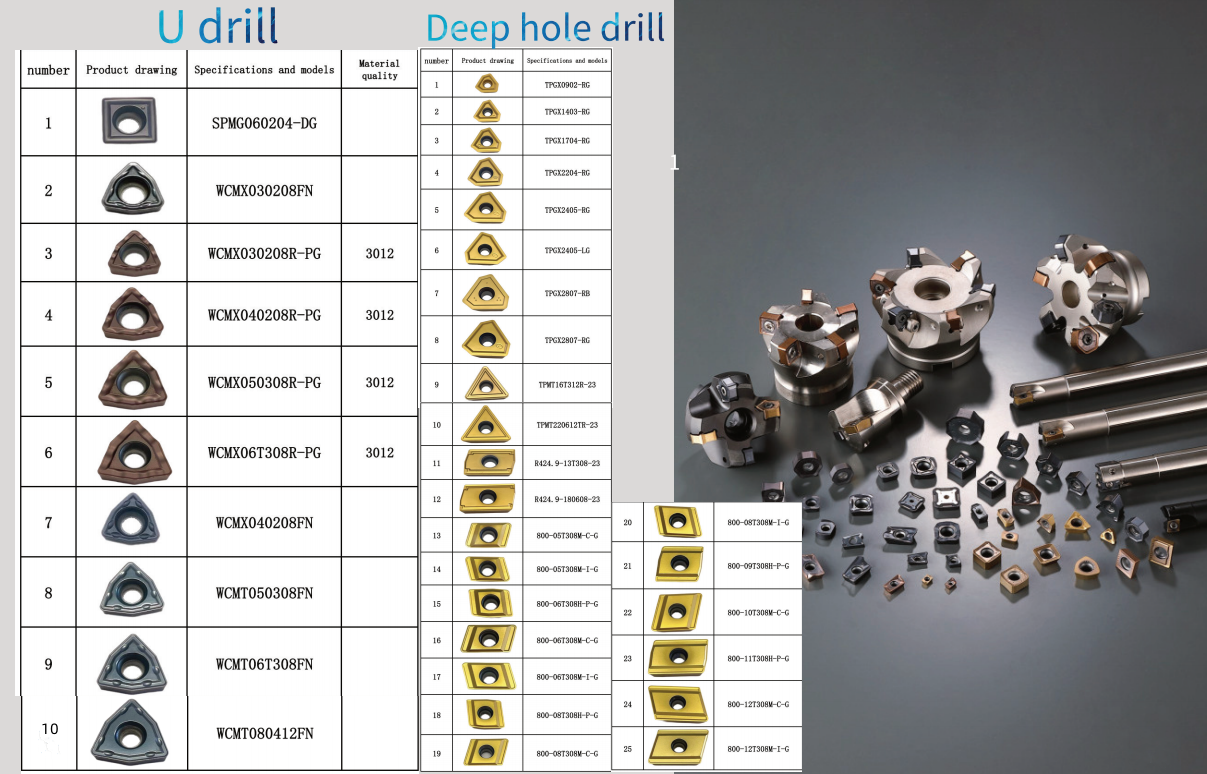

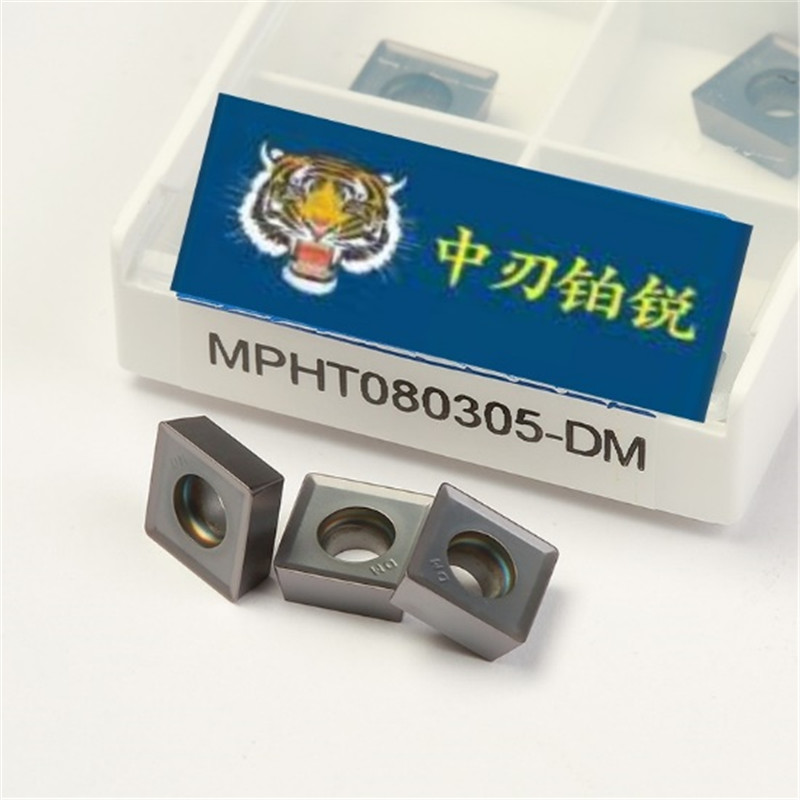

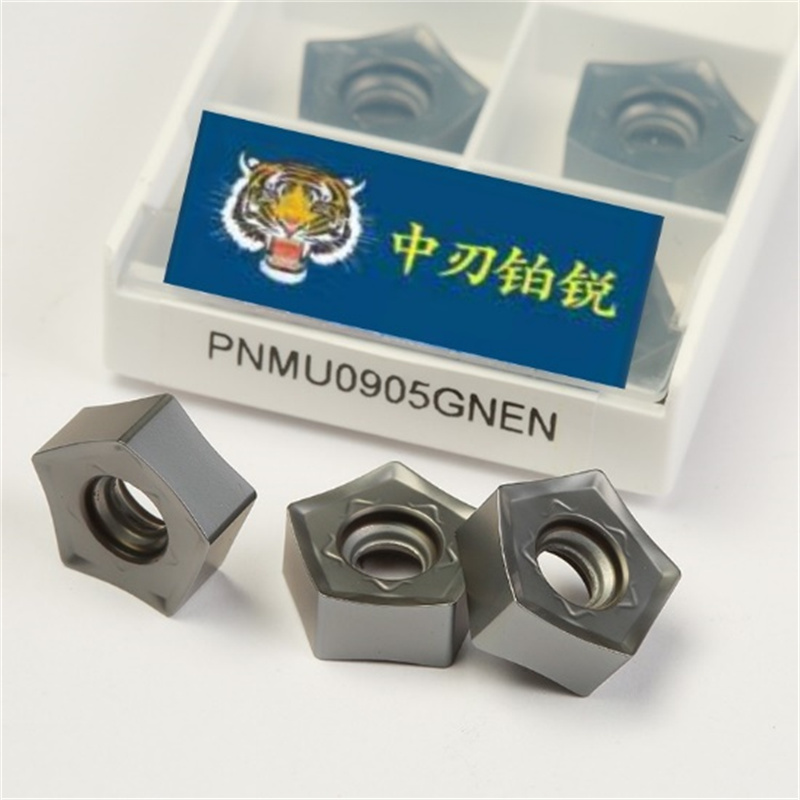

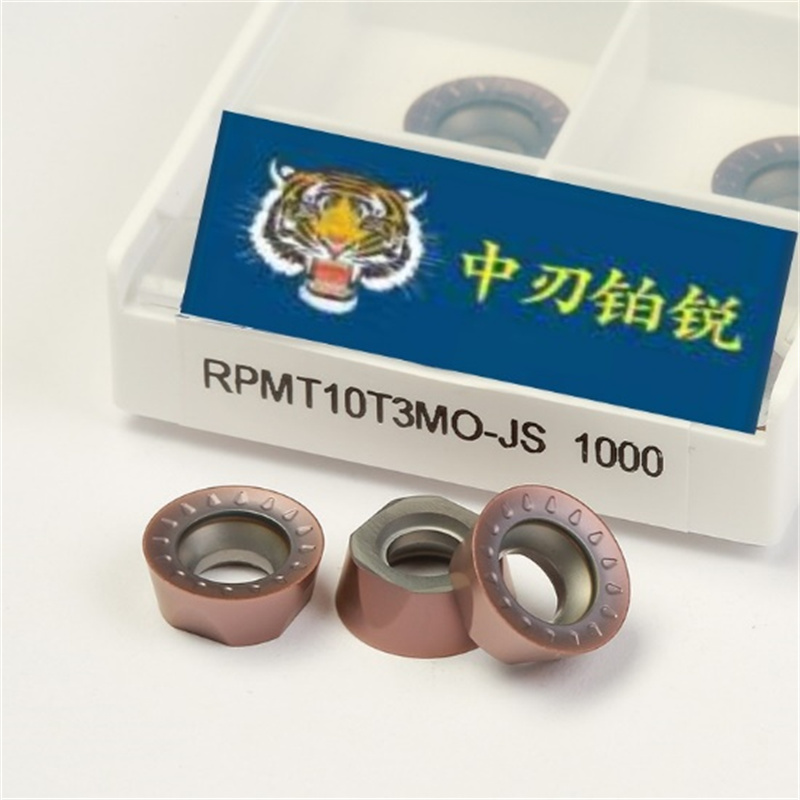

re ka hlahisa mefuta e fapaneng ea lisebelisoa tsa ho itšeha tsa tungsten carbide ho ea ka litšoantšo tse fapaneng tse hlophisitsoeng.

re ka fana ka litharollo tse tšehetsang ka kakaretso bakeng sa tšimo ea machining.

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

Litifikeiti

Melemo

1. Ho rarolloa ka katleho ho haha mosebetsi o thata le mathata a mang a machining.

2. Ho khethoa ha maemo a holimo ho molemo ho laola tsela ea phallo ea chip le ho fumana boleng bo holimo bo holimo.

3. Sekhahla se bohale, matla a manyenyane a ho itšeha.

4. Molemo machining holim boleng.

5. Moralo o khethehileng oa chip breaker ho boloka bohale le ho sireletseha.

6. Molemo oa anti impact resistance.

7. Excellent sesebelisoa bophelo nako.

Likaroloana

1.e khethehileng holim'a phekolo ka ho roala.

2.suit bakeng sa ts'ebetso e phahameng ea ho nepahala.

3.ho fana ka potlako le tšebeletso ea boleng bo holimo.

4. Boleng bo phahameng ka theko ea tlhōlisano.

5. E sebelisoa haholo indastering ea mechine ea tšepe

6. Ho nepahala ho phahameng, ho nkela sebaka habonolo, tšebeliso e akaretsang.