Carbide ea boleng bo botle e kenya ka hare ho Deep Hole Threading Milling Insets 16UI DE60

Litaba tsa Motheo

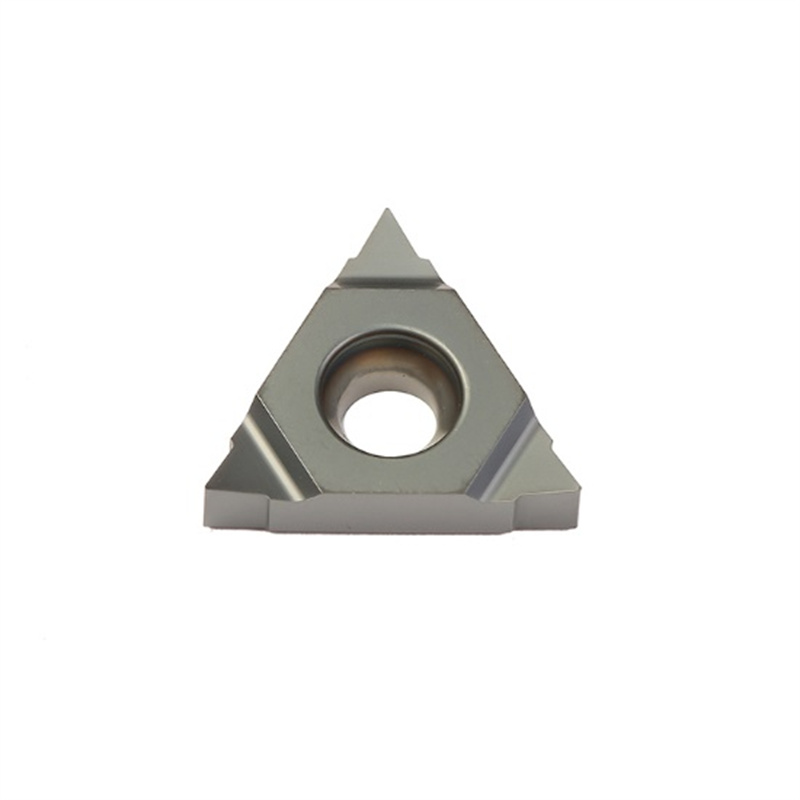

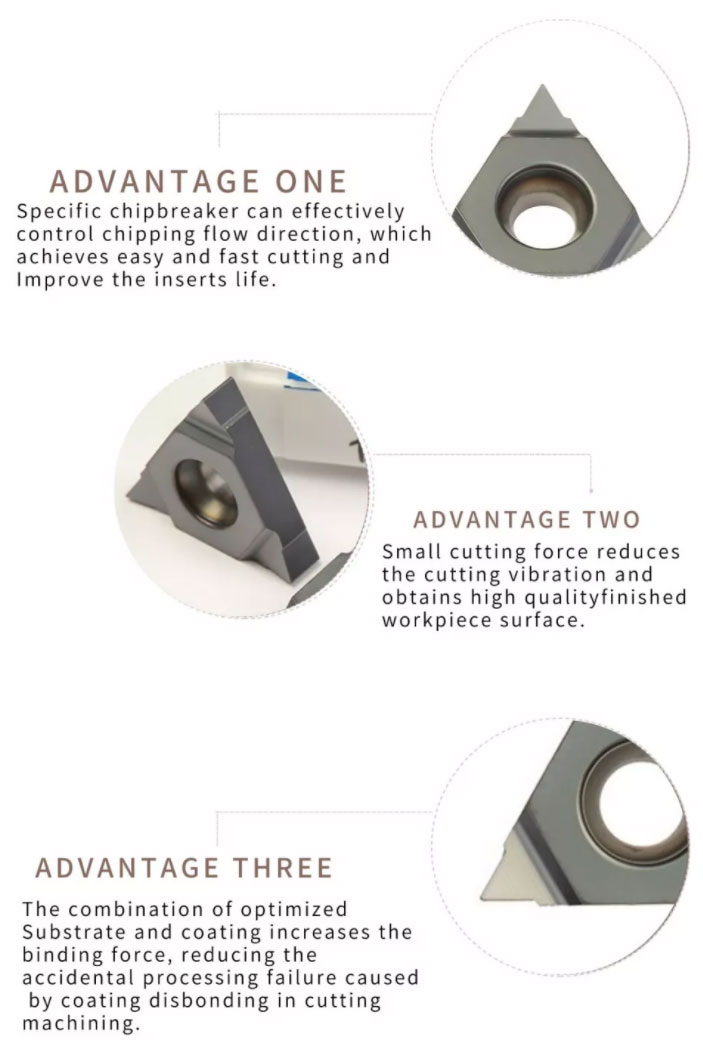

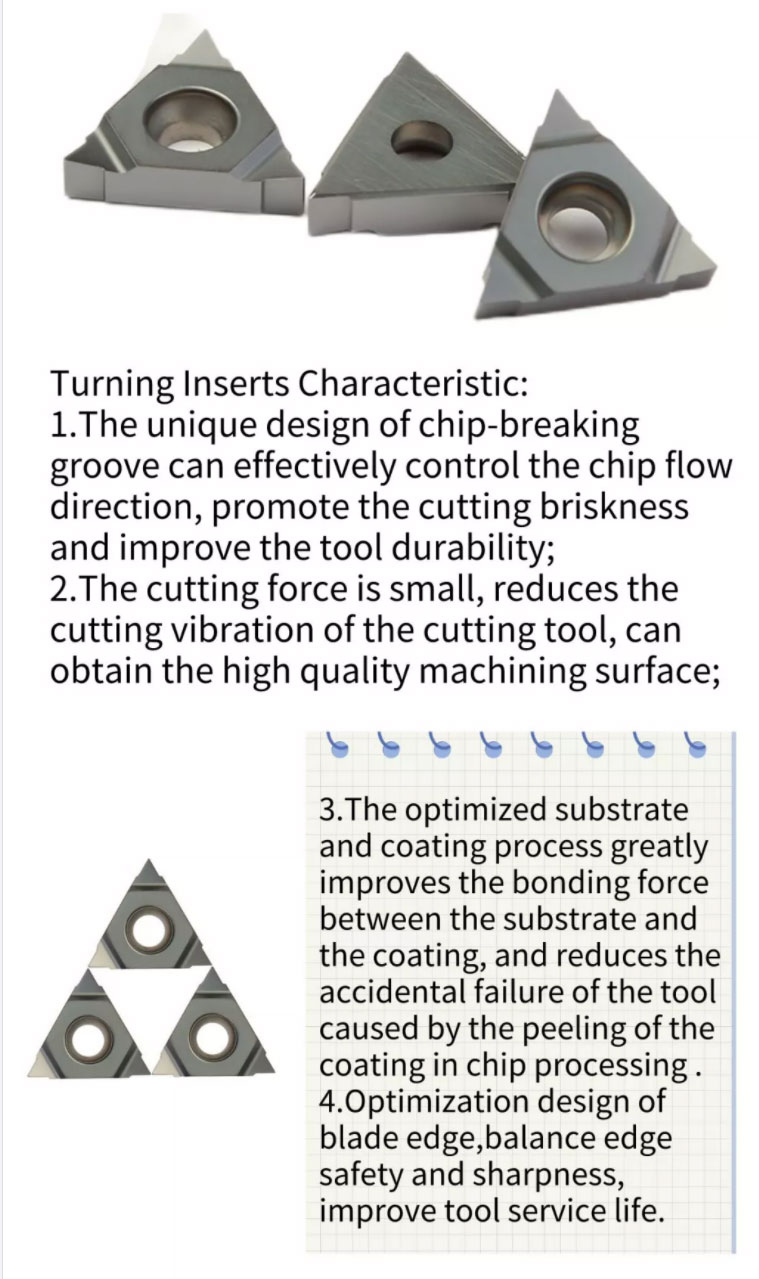

Khetha sesebelisoa se tsitsitseng sa ho itšeha moralo o ikhethang oa tšepe, fokotsa tlhahiso ea chip, maemo a loketseng a ho itšeha, bohale ba harepa bo sa sebetseng, bakeng sa ho qeta tšepe.

Likaroloana

1. Lintho tse sa sebetsaneng haholo tse etselitsoeng ho sebetsa ka tšepe e sa hloekang

2. Boemo bo nepahetseng le ho nepahala ho phahameng

3. Sistimi e thata ea taolo ea boleng ho netefatsa boleng bo tsitsitseng

4. Sebaka se nepahetseng le se bentšitsoeng, se nang le phello e phethahetseng ea ho itšeha

5. Ho roala ha PVD ho netefatsa bophelo bo bolelele ba sesebelisoa.

Litlhaloso tsa Sehlahisoa

Pontšo ea ho roala

Litifikeiti

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

LBH

- Re bo-mang?

1.Re setsebi sa lisebelisoa tsa CNC, khamphani e thehiloe qalong ea lipatlisiso le nts'etsopele ea li-blades tsa CNC tsa carbide le tlhahiso.E ipapisitse le boiphihlelo ba lilemo tse sebetsang tlhahisong, k'hamphani e bokelletse boiphihlelo bo bongata ho hlahiseng le ho sebetsa.Hona joale, k'hamphani e thehile likarolo tsa tšepe, castings, tšepe e sa hloekang kaba sebetsa, seka-felisang haholo-holo cha, o fihlile boemong bo ka sehloohong ba malapeng.

2. Re ka tiisa boleng ba eona joang?

Re na le sehlopha sa rona sa lipatlisiso tsa mahlale le sehlopha sa tlhahiso, ho tloha ho batching ho ea ho tobetsa, passivation, polishing le lihokelo tse ling li na le tlhahlobo e khethehileng ea boleng, ts'ebetsong ea tlhahiso ea sampling ea lehare, pele ho tlhahiso ea boima, re tla hlahisa palo e nyane ea lisampole esale pele bakeng sa tse nyane. tlhahlobo ea batch;Thepa e ntse e ka hlahlojoa ka lekhetlo la ho qetela.

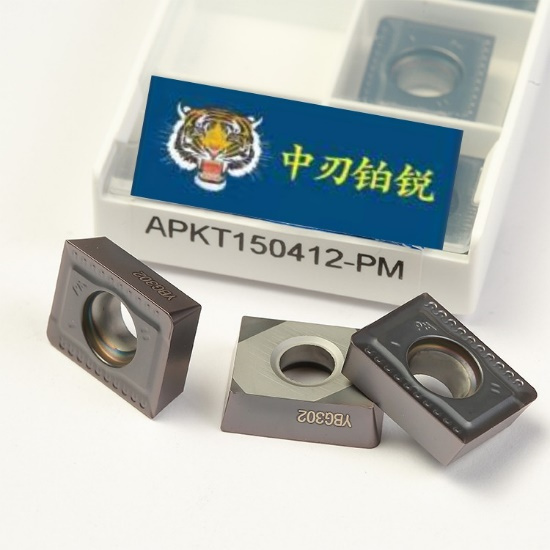

3. U ka reka eng ho rona?

Lisebelisoa tsa ho itšeha tsa CNC, li-blades tsa CNC, li-blades tsa carbide, likarolo tsa lisebelisoa tsa mochine, likotoana tsa ho cheka li-carbide, li-milling cutters, li-drill tse nang le sebopeho sa U, lisebelisoa tsa lisebelisoa, lithulusi le lisebelisoa tse ling.

4. Ke hobane'ng ha u batla ho reka ho rona ho e-na le barekisi ba bang?

Re baetsi ba lisebelisoa tsa CNC, groove e ikemetseng ea lipatlisiso le nts'etsopele le theknoloji e tsoetseng pele ea tlhahiso, thekiso e tobileng ea feme, boleng bo botle, theko e tlase, melemo e felletseng ea ts'ebetso ea litšenyehelo, e loketseng litlhoko tse fapaneng tsa bareki.