Quality Good WNMU080608 Gray kapa Yellow Milling Carbide Insets CNC Cutter High Feed Face Milling Insets

Kopo

- NO ea mohlala: WNMU080608-GM

- Tšebeliso: Ho sila sefahleho

- OEM / ODM: Fana ka

- Mosebetsi: tšepe e se nang tšepe le tšepe ea Cast

- lintho tse bonahalang: Carbide, Tungsten Cobalt Alloy

- Seaparo:Tiain

- Sehlopha sa ISO:P10-P20,M05-M15

- Sephutheloana sa Lipalangoang: Pele se phuthetsoe ka lebokose la polasetiki ebe se phutheloa ka kariki

- Khoutu ea HS

- 8208101900

Kopo

Tšebeliso ea mantlha:Bakeng sa ho sebetsa tšepe ea carbon, tšepe e entsoeng ka tšepe, tšepe e sa hloekang

Indasteri ea kopo:

CNC ho fetola le ho sila lihlahisoa tsa lihlahisoa tsa lihlahisoa tsa tungsten carbide li sebelisoa haholo ho: Indasteri ea ho etsa likoloi, indasteri ea tlhahiso ea Mold, indasteri ea lifofane, indasteri ea ts'ireletso, indasteri ea ho sebetsa ka matla le tse ling tse ngata.

re ka hlahisa mefuta e fapaneng ea lisebelisoa tsa ho itšeha tsa tungsten carbide ho ea ka litšoantšo tse fapaneng tse hlophisitsoeng.

re ka fana ka litharollo tse tšehetsang ka kakaretso bakeng sa tšimo ea machining.

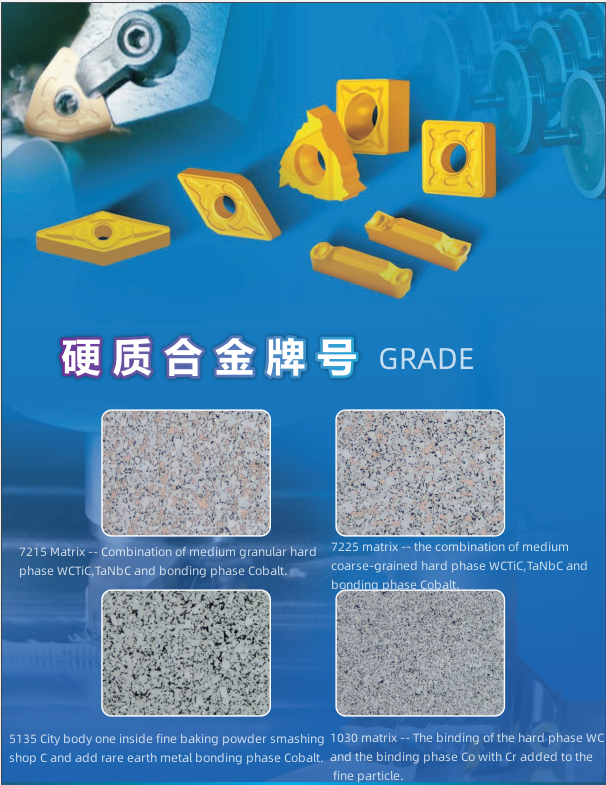

Material Grade Kenyelletso

Kenyelletso ea lintho tse fetohang:

7215 e na le matla a phahameng le ho tiea ha matrix a chefo e phahameng, e kopantsoeng le MT-TICN, AL2O3, TIN e kopantsoeng hantle ea ts'ebetso ea ho roala, 'me ka mor'a ho koaheloa ka mor'a kalafo ho felisa khatello ea ka hare ea lehare la lehare, le loketseng ho qeta tšepe e tloaelehileng.

Tšireletseho ea 7125 ea matla a phahameng, boima bo phahameng ba matrix bo kopantsoeng le MT-TICN le ts'ebetso ea ho roala ea superfriction AL203, ebe ka mokhoa o tsoetseng pele oa ho roala ka mor'a phekolo ho felisa khatello ea ka hare ea ho roala, e loketseng ts'ebetso e tloaelehileng ea tšepe, ho qeta halofo le karolo ea litlhoko tsa workpiece roughness ha ba phahameng ho qeta.

4025 high corrosion resistance, le ka ts'ebetso e itseng ea khatello ea khatello ea matrix a matla a phahameng le MT-TICN le motsoako o motle haholo oa AL2O3 oa ho roala, o nang le theknoloji e tsoetseng pele ea ho roala ka mor'a kalafo ho fumana bokaholimo bo boreleli, bo loketseng mochini o thata, o qetang halofo. le ho qeta tšepe e entsoeng ka tšepe.

1030 lijo-thollo tse ntle, khanyetso e ntle ea deformation le ka ts'ebetso ea sintering ea khatello ea ho fumana matla a holimo-limo le matrix a ho hanyetsa, ka mokhoa oa ho roala ka nano PVD, ebe ka mor'a kalafo e tsoetseng pele ea ho roala ho fumana bokaholimo bo boreleli, bo loketseng ho phethela tšepe e tloaelehileng, quenched steel, chromium plated steel and stainless steel semi-finishing and finishing.

1120 lijo-thollo tse ntle haholo, khanyetso e ntle ea deformation, le ka ts'ebetso ea sintering ea khatello ho fumana matla a phahameng le ho roala matrix, e nang le nano SI e nang le ts'ebetso ea ho roala ea PVD, kamora ho koaheloa ka morao ho kalafo ho fumana bokaholimo bo boreleli.E loketse bakeng sa grooving le ho itšeha ka tšepe e tloaelehileng, tšepe e thata le tšepe e entsoeng ka tšepe.

Kenyelletso ea lisebelisoa tsa ho sila le ho cheka

Ho roala ha 1030 NC-TIALN ho kopantsoe le matrix a matla le a ductile a likaroloana tse ntle li loketse ho sila mahoashe le ho qeta mefuta eohle ea thepa e entsoeng.Ho phunya, ho seha le ho phunya ha halofo ea aperture.

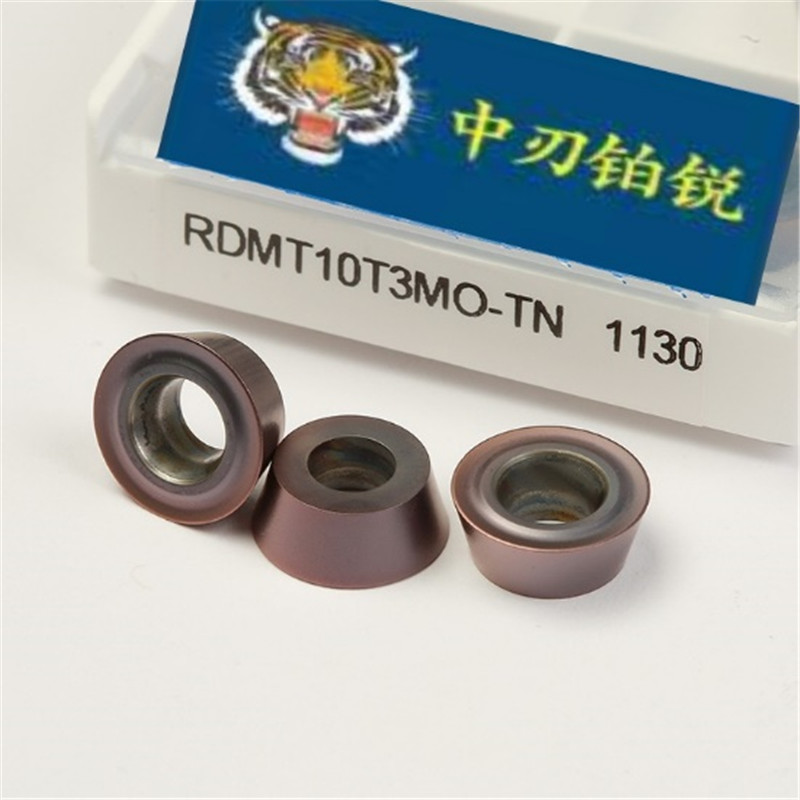

1130 NC-TIALN coating e nang le SI e kopantsoe le likaroloana tse ntle le boima bo botle ba matrix a alloy alloy, a loketseng tšepe e sa hloekang, karolo ea tšepe e entsoeng ka tšepe le ho qeta ho sebetsa, ho finyella motsoako o phethahetseng oa polokeho le ho hanyetsa ho apara.

5035 e kenyellelitse ho roala le likarolo tse phahameng tsa ho hanyetsa mocheso oa ho roala ha CVD, boima bo phahameng ba ho roala le ho hanyetsa mocheso o phahameng haholo ho fana ka tšireletso e sebetsang bakeng sa ho itšeha, theknoloji e khethehileng ea phekolo ea ho roala, ho roala le matrix ka mokhoa o tiileng, o loketseng mocheso o phahameng oa mocheso, lisebelisoa tsa titanium alloy ho nepahala. ts'ebetso ea ho sila.

5135 NC-TIALN coating e nang le SI e kopantsoeng le matrix ea carbide e nang le ts'ebetso e matla haholo, e loketseng likarolo tsa tšepe, tšepe e sa hloekang, grooving, seha se tebileng, ho fepa ka potlako le ho cheka ho hoholo ha metsi.

Litlhaloso tsa Sehlahisoa

Pontšo ea ho roala

Litifikeiti

Lisebelisoa tsa Tlhahiso

Lisebelisoa tsa QC

Melemo

1.Tungsten carbide lintho tse bonahalang

2.Setoko se seholo se ka fana ka potlako

3.Ho apara ka holimo le ho hanyetsa abrasive

4.Theko e khahlehang le boleng bo phahameng ka tšebeletso e ntle

5.Precision fatše le bentšitsoe

Tšebeletso ea rona:

Re boetse re amohela tlhoko ea moreki

Bongata bo fapaneng bo ipapisitseng le litlhoko tsa moreki

Basebetsi ba nang le talenta le ba koetlisitsoeng hantle

Ho nepahala ho phahameng le ts'ebetso e ntle

Haeba u batla ho tseba lintlha tse eketsehileng bakeng sa lihlahisoa tsa rona, ka kopo Se ke oa tsilatsila ho ikopanya le rona moleng.